- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Machining center turning drilling and boring

Drilling and boring are two common and important operations during the machining process of CNC machining centers....

Drilling and boring are two common and important operations during the machining process of CNC machining centers. Here is some basic information about both operations:

CNC machining center drilling is a commonly used method in the processing process, which mainly uses drill bits to process holes in solid materials. This operation is particularly common in geological exploration work and is used to form a cylindrical circular hole with a smaller diameter and a larger depth, also known as drilling. During operation, it may be necessary to use a center drill for positioning and use a drill bit 0.5 to 2mm smaller than the drawing size for initial drilling. If further improvement of accuracy is required, finishing can also be performed.

Boring is the further processing of existing holes to enlarge the hole diameter, improve accuracy, reduce surface roughness, and correct the deflection of the hole axis. Boring operations typically require the use of a center drill for positioning, followed by a rough boring tool or milling cutter for most of the machining, and finally a pre-sized fine boring tool for fine boring.

In actual operation, the sequence and parameter settings of drilling and boring of CNC machining centers may be adjusted according to the specific workpiece and processing needs. For example, in some cases drilling may be performed as a preliminary machining step and boring as a subsequent fine machining step.

In general, CNC machining center drilling and boring play an important role in the CNC machining center's processing process. The CNC machining center can accurately process holes that meet the requirements to meet the needs of various industrial applications.Drilling and boring are two common and important operations during the machining process of CNC machining centers. Here is some basic information about both operations:

CNC machining center drilling is a commonly used method in the processing process, which mainly uses drill bits to process holes in solid materials. This operation is particularly common in geological exploration work and is used to form a cylindrical circular hole with a smaller diameter and a larger depth, also known as drilling. During operation, it may be necessary to use a center drill for positioning and use a drill bit 0.5 to 2mm smaller than the drawing size for initial drilling. If further improvement of accuracy is required, finishing can also be performed.

Boring is the further processing of existing holes to enlarge the hole diameter, improve accuracy, reduce surface roughness, and correct the deflection of the hole axis. Boring operations typically require the use of a center drill for positioning, followed by a rough boring tool or milling cutter for most of the machining, and finally a pre-sized fine boring tool for fine boring.

In actual operation, the sequence and parameter settings of drilling and boring of CNC machining centers may be adjusted according to the specific workpiece and processing needs. For example, in some cases drilling may be performed as a preliminary machining step and boring as a subsequent fine machining step.

In general, CNC machining center drilling and boring play an important role in the CNC machining center's processing process. The CNC machining center can accurately process holes that meet the requirements to meet the needs of various industrial applications.

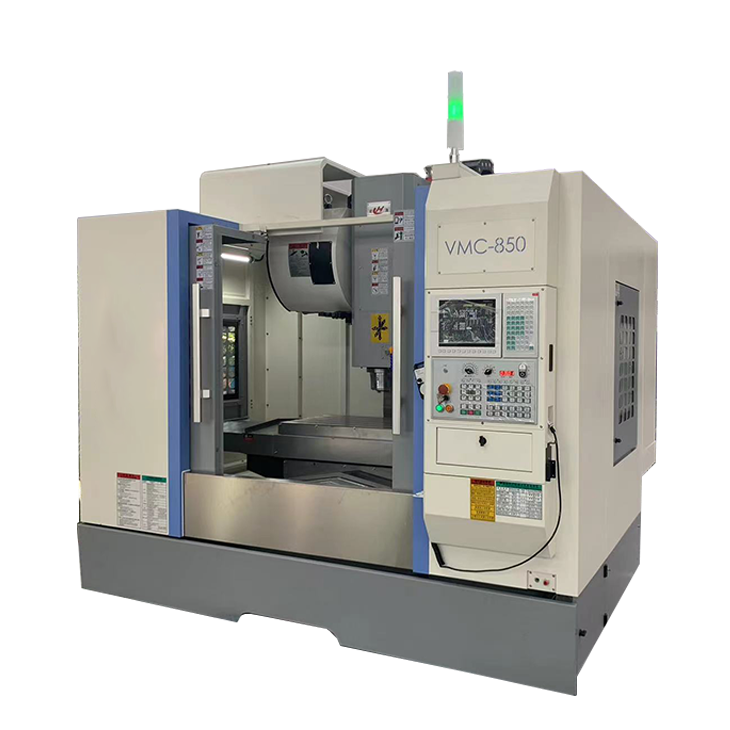

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды