- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

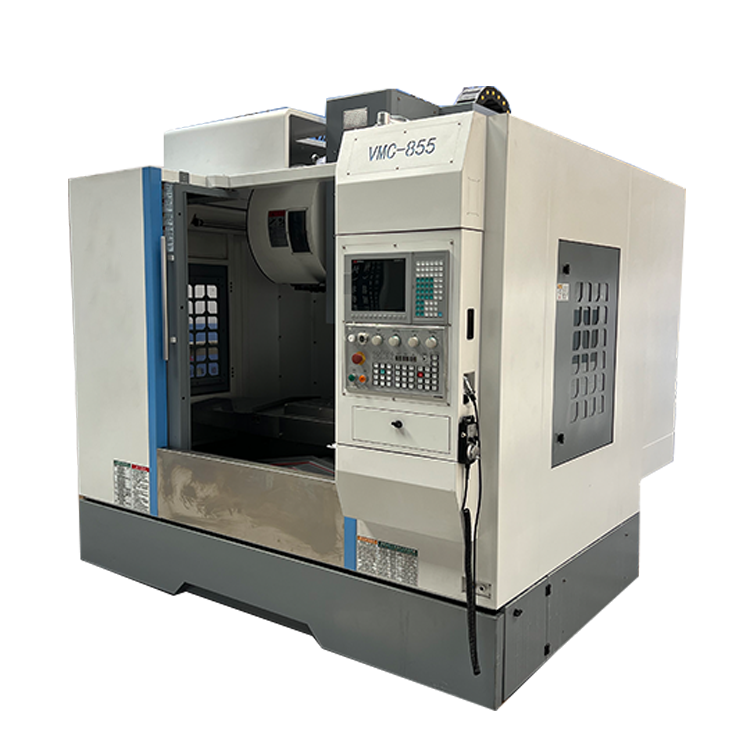

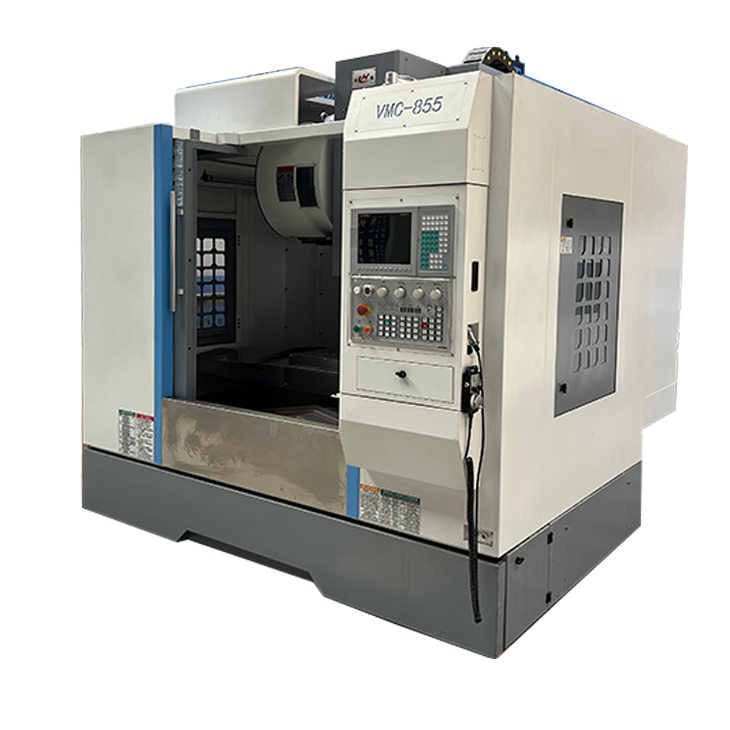

Precision mold cutting processing center

The precision mold cutting machining center is a CNC machine tool dedicated to manufacturing precision molds....

The precision mold cutting machining center is a CNC machine tool dedicated to manufacturing precision molds. It has the characteristics of high precision, high stability and high efficiency, and is specially used to process molds that require high precision, complex shapes and high surface quality. The following are some of the main features and applications of precision mold cutting machining centers:

1. High-precision processing: The precision mold cutting machining center has high-precision processing capabilities and can achieve micron-level processing accuracy. This is crucial for manufacturing high-precision molds and precision parts.

2. High stability: This type of machining center usually adopts a solid machine tool structure and a high-performance CNC system to ensure the stability and reliability of the machining process and help maintain the stability of machining accuracy and surface quality.

3. Multi-axis control: Precision mold cutting machining centers usually have multi-axis control functions, which can achieve more complex processing operations, such as cutting and engraving in multiple directions, thereby achieving more complex mold shapes.

4. High-speed cutting: This type of machining center is usually equipped with a high-speed spindle and a high-speed feed system, which can achieve high-speed cutting, improve processing efficiency, and reduce thermal deformation during processing.

5. High surface quality requirements: Since precision molds usually require extremely high surface quality, precision mold cutting machining centers are usually equipped with high-precision tools and surface processing functions to ensure the smoothness and accuracy of the processed mold surface.

6. Suitable for various materials: This type of machining center can process various materials, including metals, plastics, ceramics, etc., so it has a wide range of applications in the mold manufacturing industry.

7. Wide range of applications: Precision mold cutting processing centers are widely used in automobile manufacturing, aerospace, electronic products, medical equipment and other fields, providing high-quality molds and parts for various industries.

Overall, precision mold cutting machining centers play an important role in the manufacturing industry. Its high precision, high stability and high efficiency provide reliable processing solutions for manufacturing high-quality molds and parts.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды