- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

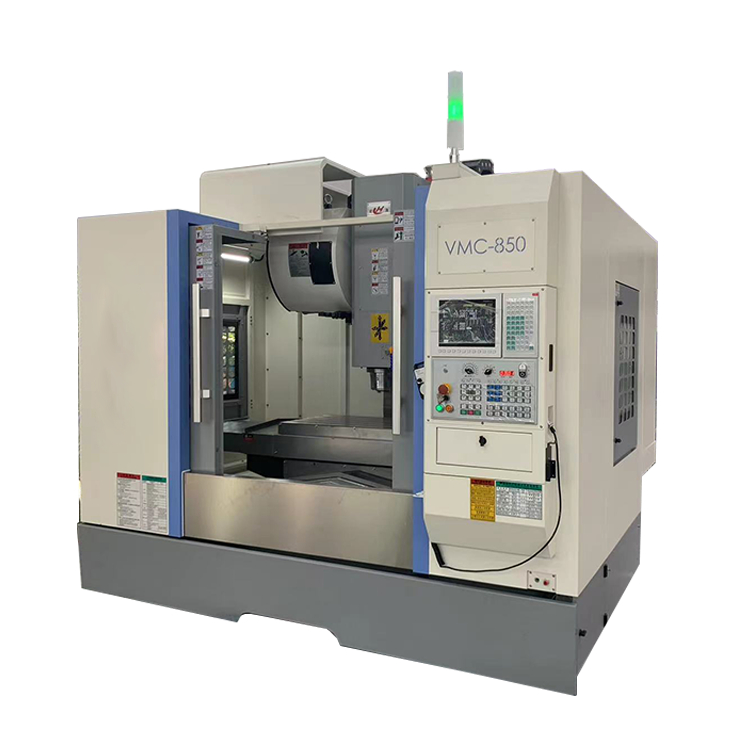

Precision positioning machining center

The precision positioning machining center is a high-precision and high-efficiency machine tool equipment, mainly used to complete various complex machining tasks....

The precision positioning machining center is a high-precision and high-efficiency machine tool equipment, mainly used to complete various complex machining tasks. The precision positioning machining center combines advanced CNC technology and precision mechanical structure to achieve high-precision positioning and processing of workpieces. Precision positioning machining centers are widely used in aerospace, automobile manufacturing, mold manufacturing and other fields.

The key to a precise positioning machining center lies in its positioning accuracy and repeatability. Positioning accuracy refers to the machine tool's ability to accurately control the position of the workpiece during processing. It directly determines the quality of the processing. Repeatable positioning accuracy refers to the consistency of the precision positioning machining center's positioning ability for the same position during multiple processing processes. This is also an important factor in ensuring processing stability and reliability.

In order to achieve precise positioning, the precision positioning machining center adopts a variety of advanced technologies and measures. For example, it uses a highly rigid machine tool structure and transmission system to reduce the impact of vibration and cutting force on positioning accuracy. At the same time, the precision positioning machining center is also equipped with a high-precision measurement and feedback system to monitor and adjust positional deviations during the machining process in real time. In addition, the precision positioning machining center also uses advanced tool and fixture technology to improve processing efficiency and accuracy.

When operating a precision positioning machining center, the operator's technical level and operating specifications also have an important impact on positioning accuracy. Operators of precision positioning machining centers need to be familiar with the operating procedures and parameter settings of machine tools, reasonably select tools and fixed workpieces, and adjust and replace tools in a timely manner to reduce processing errors.

In general, the precision positioning machining center is an efficient and accurate machine tool equipment. Its application can significantly improve the processing quality and production efficiency, and meet the manufacturing industry's demand for high-precision and high-efficiency processing. With the continuous development of manufacturing technology, precision positioning machining centers will be more widely used and popularized.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды