- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

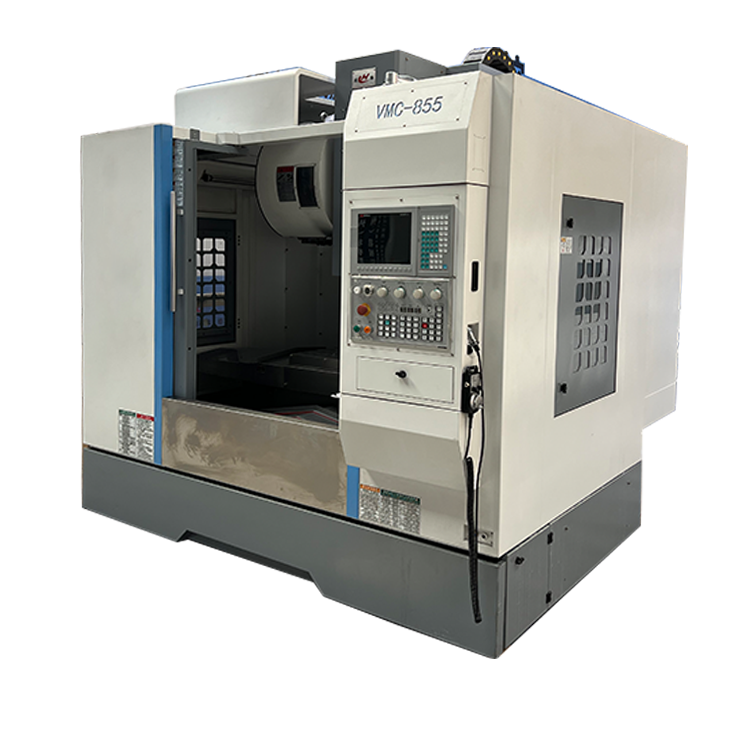

Small machining center with stable performance

The machining center is a flexible and efficient manufacturing tool suitable for many industrial fields that require high precision, high efficiency and complex shape processing. It is used to process various metal, plastic and composite parts....

The machining center is a flexible and efficient manufacturing tool suitable for many industrial fields that require high precision, high efficiency and complex shape processing. It is used to process various metal, plastic and composite parts. They can be used to produce automotive parts, aerospace components, electronic equipment, industrial machinery, and more. Small machining centers have some key features and measures to maintain performance stability:

1. Machine tool structure design:

Solid structure: Small machining centers usually adopt a solid machine tool structure to ensure sufficient stability during operation. This includes high-quality machine tool materials and reasonable structural design to resist vibration and deformation.

2. High-precision guide rails and screws:

Precision motion system: Small machining centers usually use high-precision linear guides and screw systems to ensure smoothness and accuracy of axial movement. This helps maintain stability and accuracy during machining.

3. Stable spindle:

Balance and Bearings: Spindle balance and high-quality bearings are key to maintaining stability. Small machining centers usually use well-designed spindle systems to ensure that no vibration or resonance occurs when running at high speeds.

4. High-performance CNC system:

Stable control system: Small machining centers use high-performance CNC systems to ensure smoothness and accuracy of motion control. These systems usually have automatic correction and real-time monitoring functions to maintain a stable machining process.

5.Temperature control:

Cooling system: Small machining centers are usually equipped with effective cooling systems to control the temperature of the machine tool and spindle. Temperature stability is critical to maintaining dimensional stability of mechanical components and preventing thermal deformation.

6. Automated tool and workpiece loading and unloading system:

Automatic tool changing and workpiece loading and unloading: Through the automatic tool changing system and workpiece loading and unloading system, small machining centers can reduce downtime during the production process, improve processing efficiency, and reduce errors caused by human operations.

7. High quality tools and tool management:

Tool quality and management: The use of high-quality tools and an effective tool management system ensures the stability of the cutting process. Regular inspection and replacement of cutting tools are important steps to maintain stable performance.

8. Quality control and inspection system:

Real-time detection: Small machining centers may be equipped with quality control and real-time detection systems to monitor any abnormalities during processing and take timely measures to adjust.

By adopting these design and technical measures, small machining centers can provide high-precision machining capabilities while maintaining performance stability. This is very important for high-quality production of small parts.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды