- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

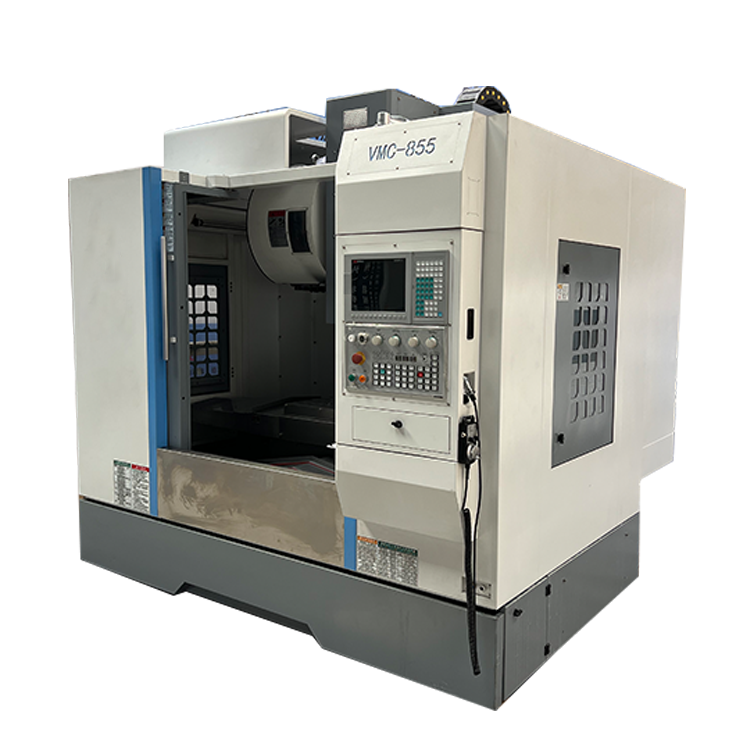

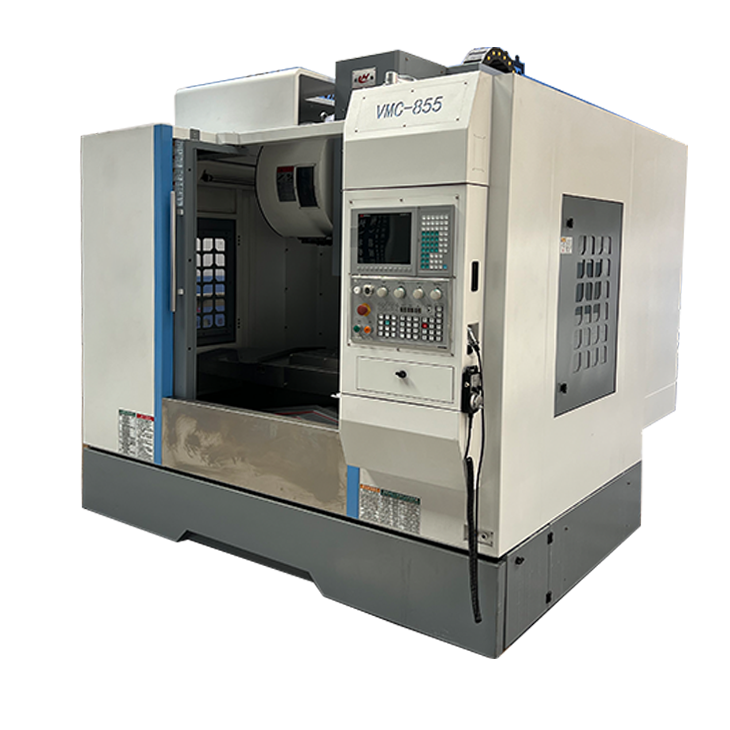

Vertical CNC machining center deep hole processing

When performing deep hole processing on a vertical CNC machining center, the following aspects need to be considered:...

When performing deep hole processing on a vertical CNC machining center, the following aspects need to be considered:

1. Tool selection: Choose a tool suitable for deep hole processing on a vertical CNC machining center. Vertical CNC machining centers are usually designed with long handles and thin necks to be able to reach deep holes and maintain processing stability.

2. Cutting parameter setting: The vertical CNC machining center sets the cutting parameters reasonably, including cutting speed, feed speed, cutting depth, etc. The vertical CNC machining center adjusts according to the workpiece material and deep hole processing requirements.

3. Cooling and lubrication: The vertical CNC machining center uses appropriate cooling and lubrication methods to keep the temperature of the tool and workpiece within an appropriate range to avoid tool wear and workpiece deformation in the vertical CNC machining center.

4. Tool cooling: Especially when processing deep holes in vertical CNC machining centers, the tools are easily deformed by heat, so effective tool cooling measures need to be adopted, such as internal cooling or external cooling.

5. Workpiece clamping: Ensure that the workpiece of the vertical CNC machining center is firmly clamped to avoid vibration and displacement of the workpiece during the processing of the vertical CNC machining center, which affects the processing quality and accuracy.

6. Processing path planning: The vertical CNC machining center adopts reasonable processing path planning. The vertical CNC machining center avoids excessive deviation of the tool during the machining process, which affects the machining effect.

7. Detection and adjustment: The vertical CNC machining center regularly detects the processing quality, and adjusts the processing parameters and processing paths in a timely manner to ensure the accuracy and quality of deep hole processing.

8. Operating skills: Vertical CNC machining center operators need to have certain processing experience and skills, and be familiar with machine tool operating procedures to ensure the safe and efficient completion of deep hole processing tasks.

Through the comprehensive consideration and control of the above aspects, the vertical CNC machining center can effectively realize the deep hole processing of the vertical CNC machining center and improve the processing efficiency and processing quality.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды