- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

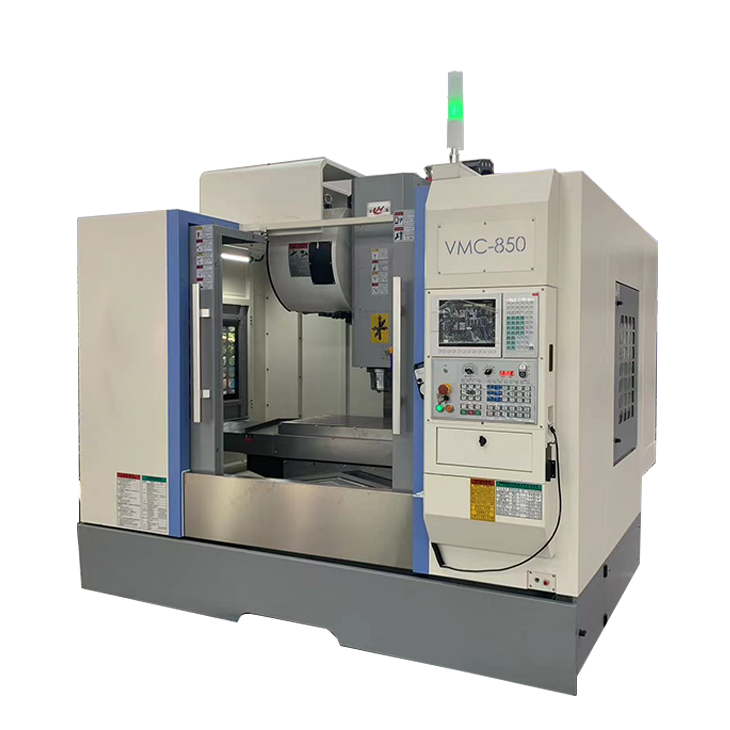

Vertical machining center automatic tool change

Vertical machining centers are often equipped with automatic tool changing systems, which help increase productivity and flexibility....

Vertical machining centers are often equipped with automatic tool changing systems, which help increase productivity and flexibility. The automatic tool change system allows automatic tool changes during machining without manual intervention. Here is some basic information about automatic tool changing systems for vertical machining centers:

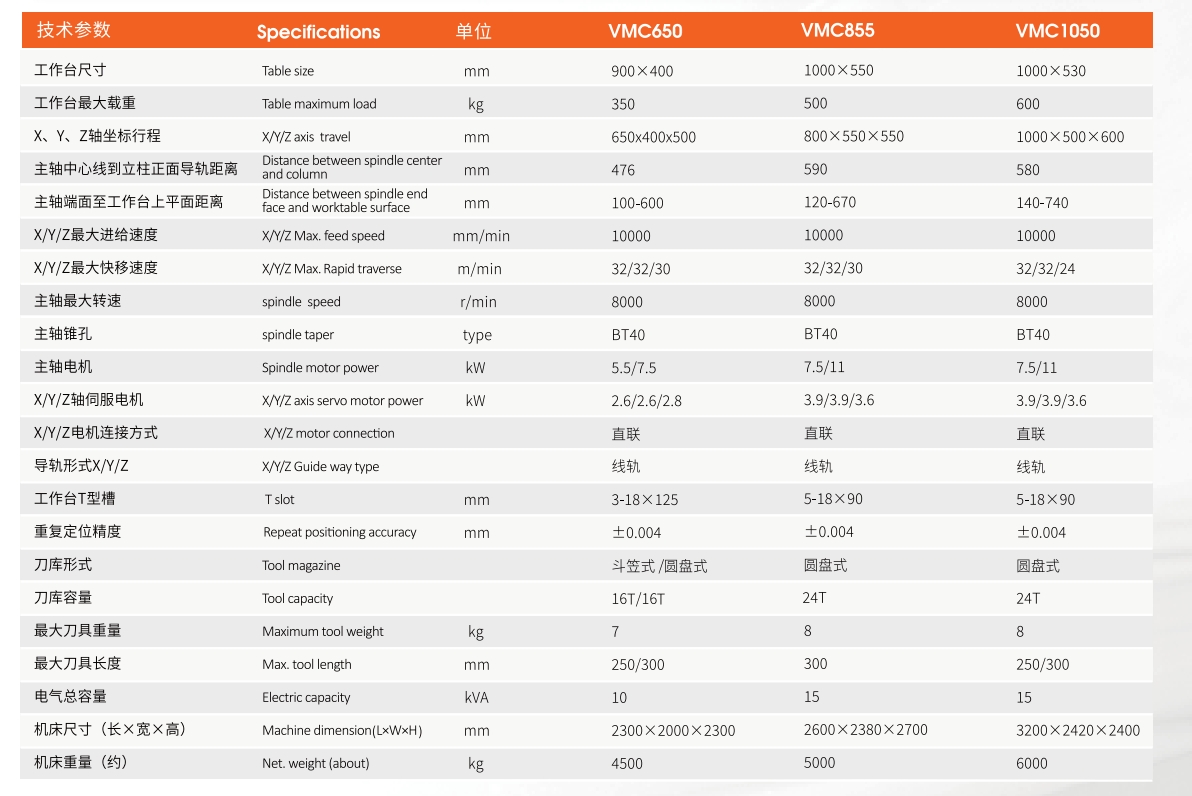

1. Tool magazine: Automatic tool changing systems usually include a tool magazine for storing multiple tools. The tool magazine can be disc type, chain type or other forms, depending on the design of the machining center and the manufacturer's choice.

2. Tool sensor: In order to realize automatic tool change, the system is usually equipped with a tool sensor. These sensors detect the location, type and status of the tool so that the system can accurately perform tool changing operations.

3. CNC system: The automatic tool changing system needs to be integrated with the CNC system to control the tool changing process. The CNC system is responsible for guiding the tool changing action and ensuring the correct selection and positioning of the tool during the cutting process.

4. Tool transfer device: A device used to transfer selected tools from the tool magazine to the spindle. This may include automatic tool changing arms, clamping jaws or other mechanical structures to ensure tool changes are completed quickly and accurately.

5. Tool length measuring device: To ensure the correct positioning of the tool after replacement, the system may include a tool length measuring device. This helps calibrate the actual position of the tool to accommodate tools of different lengths.

Advantages of automatic tool changing systems include:

1. Improve production efficiency: There is no need to stop and wait for manual tool replacement. The automatic tool change system can quickly and efficiently complete tool replacement during the machining process.

2. Increased flexibility: Allows the use of different types of tools on the same workpiece, thereby increasing the scope of application and flexibility of the machining center.

3. Reduce manual intervention: Automatic tool changing reduces operator intervention, reduces the risk of operating errors, and improves the consistency and accuracy of processing.

4. Adapt to a variety of processing needs: A variety of cutting tools can be used in the same process to adapt to different processing needs, such as rough machining, finishing, etc.

It is important to note that specific automatic tool change system design and performance may vary by manufacturer and model. Before use, it is recommended to consult the user manual or technical specifications of the corresponding CNC machining center to learn detailed automatic tool changing system information.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды