- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

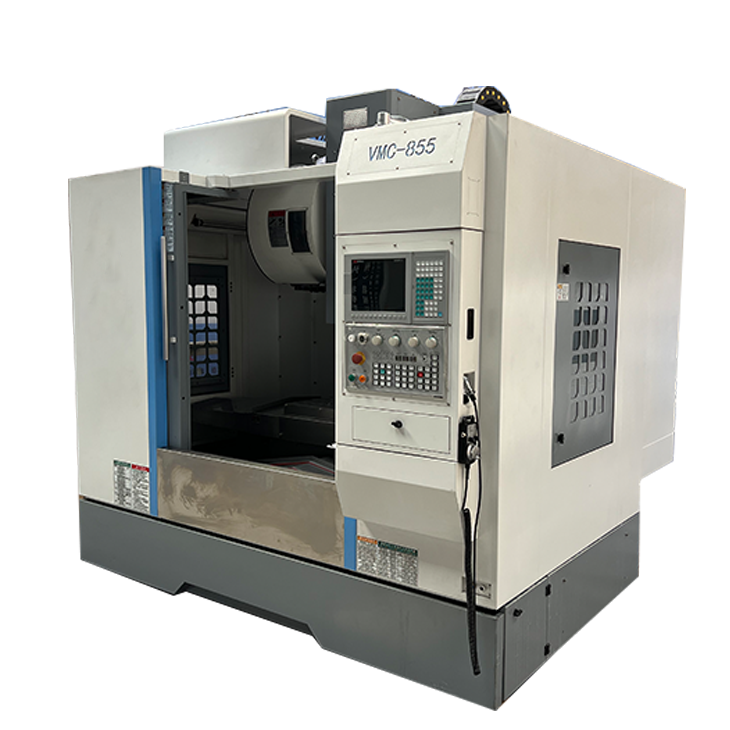

Vertical machining center automatic cutting

When performing high-performance automated cutting on a vertical machining center, there are several key aspects to consider and optimize:...

When performing high-performance automated cutting on a vertical machining center, there are several key aspects to consider and optimize:

1. Automation system: High-performance automatic cutting of vertical machining centers requires a reliable automation system that can realize rapid clamping of workpieces, automatic replacement of tools, and automatic control of the processing process. This includes the use of automatic tool changing systems, automatic clamping and automated CNC programming.

2. High-speed cutting technology: High-performance automatic cutting of vertical machining centers usually requires the use of high-speed cutting technology. This involves high-speed tools and high-speed feeds to achieve higher machining efficiency and better surface quality.

3. Tool selection and optimization: Vertical machining centers select high-performance tools suitable for automatic cutting, and optimize tool paths and cutting parameters to maximize production efficiency and cutting quality. This may involve the use of advanced tool materials and coating technologies to improve tool life and cutting performance.

4. Cutting parameter optimization: The vertical machining center accurately optimizes cutting parameters, including cutting speed, feed speed, cutting depth and cutting width. Vertical machining centers can achieve higher productivity and better processing quality by optimizing cutting parameters.

5. Real-time monitoring and feedback: The vertical machining center monitors the cutting status and machine tool performance in real time during the automatic cutting process, and promptly discovers and solves potential problems to ensure the processing quality and production efficiency of the vertical machining center. This may involve the use of sensors and monitoring systems, as well as real-time data analysis and feedback control.

6. Adaptive control technology: Vertical machining centers use adaptive control technology to automatically adjust cutting parameters and processing strategies based on real-time monitored cutting status and workpiece characteristics to achieve the best processing results and cutting performance.

7. Safety and stability: Ensure the safety and stability of the automatic cutting process of the vertical machining center, including regular maintenance and inspection of machine tools and automation systems, and the development of appropriate safety operating procedures and emergency response plans.

Vertical machining center Through the above measures, vertical machining center can achieve high-performance automatic cutting, improve production efficiency, reduce costs, and meet the needs of applications with high processing quality and precision requirements.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды