- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

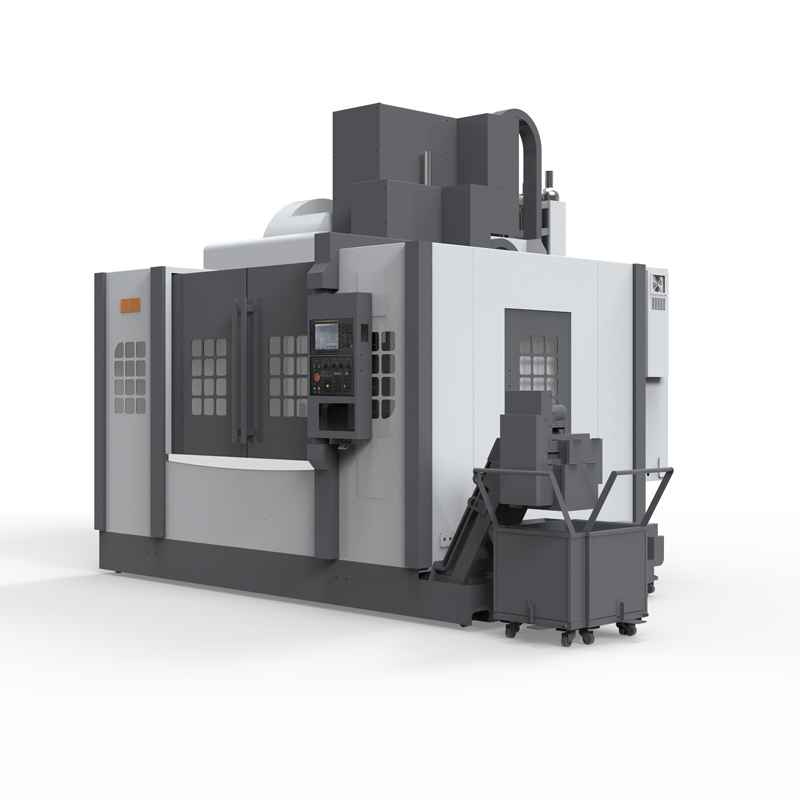

Vertical milling machine center

Vertical milling machining center is a common CNC machine tool used for milling various parts....

Vertical milling machining center is a common CNC machine tool used for milling various parts. It has the following features and advantages:

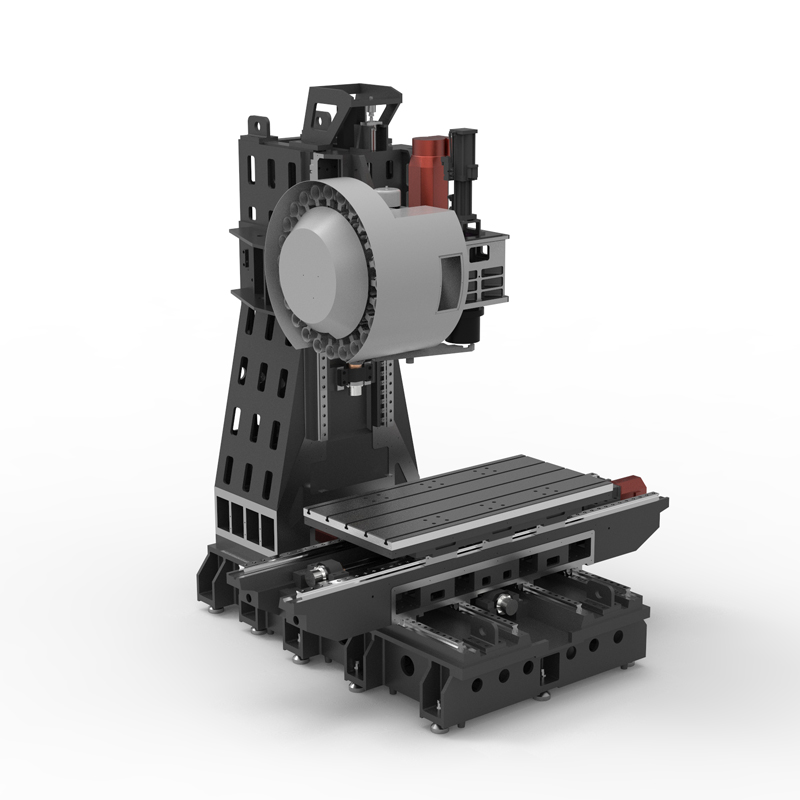

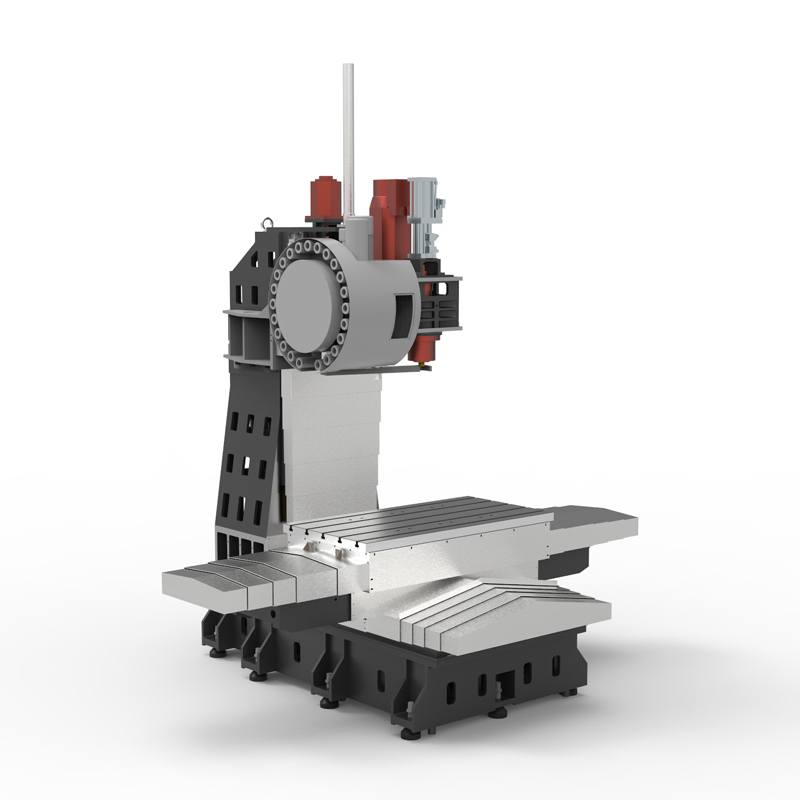

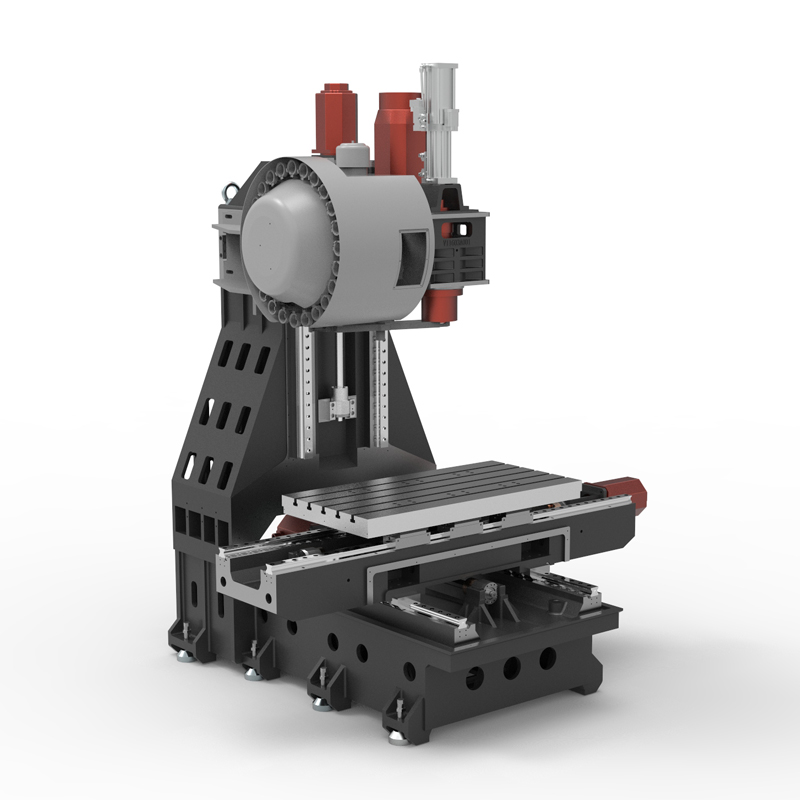

1. Structural features: The spindle of the vertical milling machine machining center is perpendicular to the work table, the workpiece is fixed on the work table, and the tool moves along three axes. This structure makes the processing process more stable and is suitable for processing complex curved surfaces.

2. Versatility: Vertical milling machine machining centers are usually equipped with multiple functions such as automatic tool changing systems and automatic workpiece changing systems, which can implement a variety of processing techniques, including milling, drilling, tapping, etc., improving processing efficiency. and accuracy.

3. Scope of application: The vertical milling machine machining center is suitable for processing various materials, including metals, plastics, composite materials, etc., and can be used to manufacture aerospace parts, automotive parts, molds, etc.

4. High-precision processing: Through CNC system control, the vertical milling machine machining center can achieve high-precision processing to ensure the size and surface quality of the processed parts.

5. High degree of automation: Vertical milling machining centers are usually equipped with CNC systems and automation devices, which can realize automated production, reduce manual intervention, and improve production efficiency and consistency.

6. Strong flexibility: The vertical milling machine machining center has a large processing range and flexible processing capabilities, which can meet the processing needs of parts of different shapes and sizes.

7. Easy operation: Through CNC programming of the vertical milling machine machining center, operators can easily write and modify processing programs, reducing human operating errors and improving production efficiency.

In general, the vertical milling machine machining center is an efficient, precise and multi-functional CNC machine tool, suitable for precision processing of various parts, and has important application value and market prospects.

| Specifications/model | unit | V966 | V1160 | V1168 | V1270 | V1377 | V1387 | V1380C | V1680C | V2010C |

| Work content | ||||||||||

| working desk size | MM | 1100×700 | 1200×600 | 1200×600 | 1300×700 | 1400×7010 | 1400×800 | 1400×800 | 1700×800 | 2100×1000 |

| Workbench travel (X/Y/Z) | MM | 900×600×600 | 1100×600×600 | 1100×600×800 | 1200×700×600 | 1300×700×700 | 1300×800×700 | 1300×800×70 | 1600×800×700 | 2000×1000×800 |

| Distance from spindle nose to work surface | MM | 150-750 | 120-720 | 120-920 | 120-720 | 120-820 | 120-820 | 150-850 | 150-850 | 150-950 |

| Distance from spindle center to column track surface | MM | 700 | 660 | 660 | 780 | 780 | 900 | 900 | 900 | 1100 |

| Maximum load of workbench | KG | 700 | 1000 | 1000 | 1100 | 1300 | 1400 | 1500 | 1800 | 2200 |

| Spindle specifications | ||||||||||

| Spindle transmission structure (standard) | / | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type |

| Spindle speed | RPM | 8000 | 8000 | 8000 | 8000 | 8000 | 8000 | 6000 | 6000 | 6000 |

| Spindle transmission structure (optional) | / | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection |

| Spindle speed | RPM | 12000 | 12000 | 12000 | 10000 | 10000 | 10000 | 10000 | 10000 | 10000 |

| Spindle power | KW | 11 | 11 | 11 | 15 | 15 | 15 | 15/18.5 | 18.5/22 | 18.5/22 |

| Spindle bore taper | BT | BT40-150 | BT40-150 | BT40-150 | BT40-150 | BT40-150 | BT40-150 | BT50-190 | BT50-190 | BT50-190 |

| Feed content | ||||||||||

| G00 rapid feed | M/MIN | 48/48/48 | 36/36/36 | 36/36/36 | 32/32/32 | 32/32/32 | 32/32/32 | 24/24/24 | 24/24/24 | 24/24/24 |

| G01 cutting feed | MM/MIN | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Servo motor specifications | NM | 22/22/22B | 22/22/22B | 22/22/22B | 22/22/22B | 22/22/22B | 22/22/22B | 40/30/30B | 40/30/30B | 40/30/30B |

| Servo motor speed | RPM | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 2000 | 2000 | 002000 |

| Motor connection method | / | Direct | Direct | Direct | Direct | Direct | Direct | Direct | Direct | Direct |

| Ball screw specifications | MM | 4016/12 | 4012 | 4012 | 4012 | 4012 | 4012 | 5010 | 5010 | 5010/6310 |

| X-axis rail specifications | MM | 45 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 55*3 roller | 55*3 roller | 55*3 roller |

| Y axis rail specifications | MM | 45 roller | 45 roller | 45 roller | 45 roller | 45 roller | 45 roller | 45 rollers*4 rails | 45 rollers*4 rails | 45 rollers*4 rails |

| Z axis rail specifications | MM | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 55*3 roller | 55*3 roller | 55*3 roller |

| Z-axis VB hard rail (optional) | / | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail |

| Precise shaft positioning | MM | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatable positioning precision | MM | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| Minimum move value | MM | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Tool magazine system | ||||||||||

| Tool magazine structure | / | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type |

| Tool magazine capacity | PCS | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Tool changing time | MM | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 4 |

| Maximum tool weight | KG | 8 | 8 | 8 | 8 | 8 | 8 | 18 | 18 | 18 |

| Oil and gas pressure system | ||||||||||

| air pressure | KG/MM | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 |

| Lubricating oil capacity | L | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| battery capacity | KW | 23 | 23 | 23 | 23 | 23 | 23 | 36 | 36 | 36 |

| coolant capacity | L | 250 | 300 | 300 | 300 | 300 | 300 | 370 | 370 | 470 |

| Form factor | ||||||||||

| Machine weight (approx.) | T | 7.5 | 8.5 | 8.8 | 9.2 | 10.2 | 11 | 12.8 | 13.8 | 16 |

| Machine length (front and rear) | MM | 2900 | 2900 | 2900 | 3000 | 3050 | 3050 | 3300 | 3300 | 3600 |

| Machine width (left and right) | MM | 3300 | 3550 | 3850 | 3950 | 4050 | 4250 | 4300 | 4650 | 5400 |

| Machine height (maximum) | MM | 2900 | 2900 | 2900 | 3100 | 3100 | 3100 | 3300 | 3300 | 3400 |

| Machine height (minimum) | MM | 2500 | 2500 | 2500 | 2650 | 2650 | 2620 | 2900 | 2900 | 3000 |

| Chip removal method (optional) | / | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate |

| Chip removal method (optional) | / | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды