- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

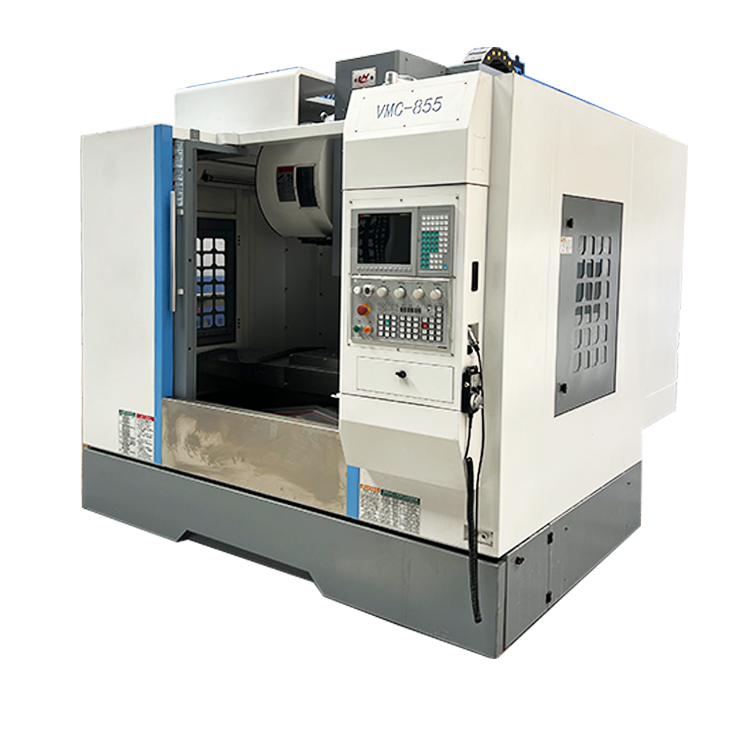

VMC 855 vertical cnc milling machining center

VMC 855 vertical CNC milling machining center has the characteristics of high precision, high efficiency and multi-function, and is suitable for precision machining of various metal and non-metal materials....

VMC 855 vertical CNC milling machining center has the characteristics of high precision, high efficiency and multi-function, and is suitable for precision machining of various metal and non-metal materials. The following are its main features and functions:

1. Vertical structure: VMC 855 vertical CNC milling machining center adopts vertical structure design, the workbench is located above the machine tool, and the tool is milled in the vertical direction. It has a small footprint and is suitable for workshop environments with limited space.

2. High-precision machining: VMC 855 vertical CNC milling machining center is equipped with high-precision CNC system and drive device, which can realize the precision machining of complex parts and provide high-precision machining quality and dimensional control.

3. Multi-axis control: VMC 855 vertical CNC milling machining center has multi-axis control function, including X, Y, Z axis linear motion and possible rotation axis motion, which can realize multi-directional machining of complex parts and improve machining efficiency and flexibility.

4. High-efficiency processing: VMC 855 vertical CNC milling machining center is equipped with high-speed spindle and automatic tool changing system, which can realize high-speed cutting and automated production, shorten the processing cycle and improve production efficiency.

5. Automation function: VMC 855 has automation functions such as automatic tool changing, automatic workpiece clamping, automatic measurement, etc., which can realize continuous processing of parts and automated production process.

6. Rigidity and stability: VMC 855 vertical CNC milling machining center has a solid machine tool structure and a stable tool support system, with good rigidity and stability, suitable for heavy load and high-precision processing requirements.

7. Easy to operate: VMC 855 vertical CNC milling machining center is equipped with an intuitive human-machine interface and an easy-to-operate CNC system. It is easy to operate, can be quickly started, and improve the operator's work efficiency and production efficiency.

8. Wide applicability: VMC 855 is suitable for the processing of various metal and non-metal materials, such as steel, aluminum, copper, plastic, etc., and can be widely used in aerospace, automobile manufacturing, mold processing and other fields.

In summary, the VMC 855 vertical CNC milling machining center has the advantages of high-precision machining, high-efficiency production, versatility, and easy operation. It is suitable for various industrial production scenarios and is a high-performance CNC machining equipment.

| Machine model | VMC650 | VMC840 | VMC850 | VMC855 | VMC966 |

| Workbench size (mm) | 1000X400 | 1000X400 | 1000X500 | 1000X550 | 1100X550 |

| Maximum allowable load (Kg) | 400 | 300 | 500 | 500 | 600 |

| X-axis travel (mm) | 650 | 800 | 800 | 800 | 900 |

| Y-axis travel (mm) | 400 | 400 | 500 | 550 | 600 |

| Z-axis travel (mm) | 550 | 550 | 500 | 550 | 600 |

| T-slot | 3-18-120 | 3-18-140 | 5-18-108 | 5-18-90 | 5-18-100 |

| Distance from spindle center to Z-axis guide surface (mm) | 485 | 445 | 552 | 590 | 663 |

| Distance from spindle end face to worktable surface (mm) | 100-650 | 100-650 | 110-610 | 120-670 | 100-700 |

| Spindle taper hole | BT40-120 | BT40-120 | BT40-140 | BT40-150 | BT40-150 |

| Spindle speed (r/min) | 8000 | 8000 | 8000 | 8000 | 8000 |

| X/Y/Z rapid movement (m/min) | 48/48/48 | 30/30/18 | 48/48/48 | 48/48/48 | 48/48/48 |

| Machine weight (Kg) | 3800 | 3200 | 5300 | 5500 | 5600 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды