- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

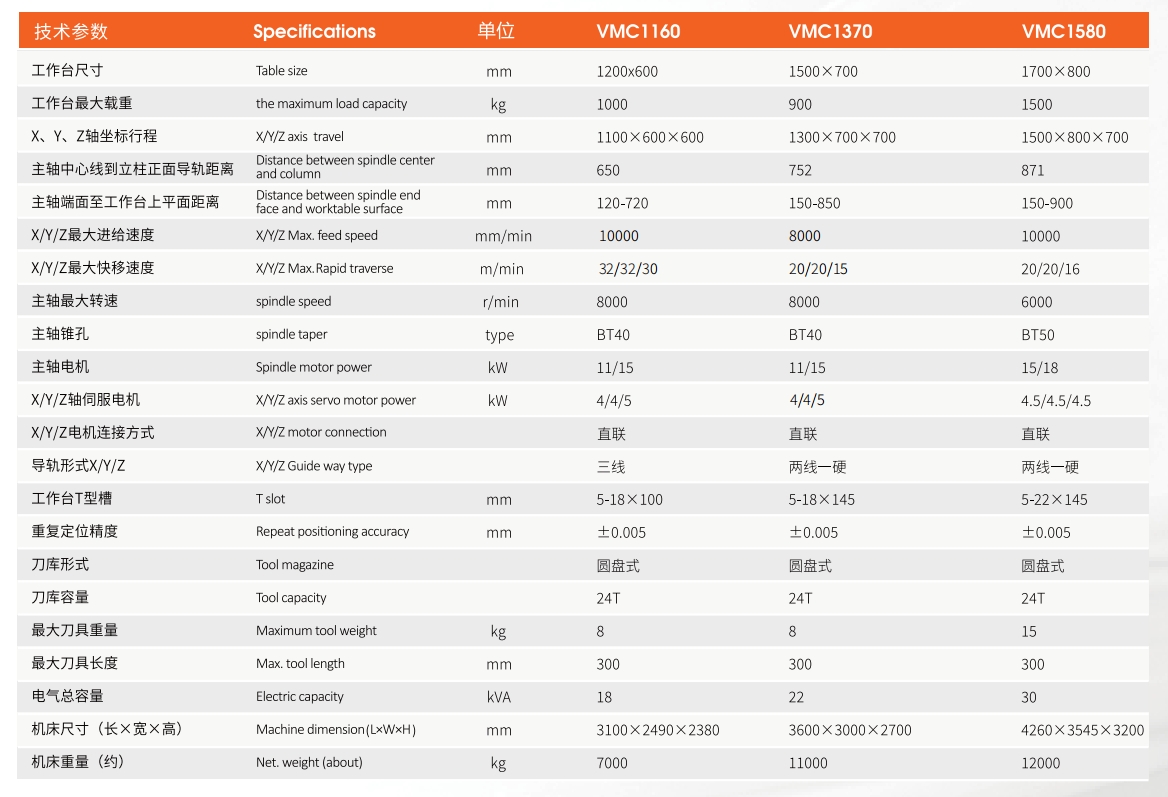

VMC1160 vertical machining center machining

VMC1160 is a type of CNC machine tool called a vertical machining center, which is commonly used in the field of machining....

VMC1160 is a type of CNC machine tool called a vertical machining center, which is commonly used in the field of machining. The following are some features and applications of the VMC1160 vertical machining center in machining:

1. High-precision processing: VMC1160 has a high-precision CNC system, which can achieve high-precision processing of workpieces. This makes it suitable for machining mechanical parts that require precise dimensions and surface quality.

2. Automation function: VMC1160 is usually equipped with an automatic tool changing system, which can accommodate multiple tools and automatically switch, improving production efficiency. At the same time, it can also have the function of automatic workpiece loading and unloading to realize the automation of the entire production line.

3. Multi-axis control: VMC1160 may have multi-axis control function, allowing multiple surfaces of the workpiece to be processed simultaneously. This multi-axis control capability increases the flexibility of the machine tool and is suitable for processing complex parts.

4. High-speed spindle: This type of machine tool is usually equipped with a high-speed spindle that can cut at high speeds. This helps improve machining efficiency, especially when cutting materials at high speeds.

5. Widely applicable materials: VMC1160 can be used to process a variety of materials, including metals, alloys, etc. This makes it more widely applicable in the field of machining.

6. CNC programming: Through CNC programming, operators can pre-set processing paths and parameters to realize automated processing of complex parts. This improves machining accuracy and consistency.

7. Suitable for small and medium-sized parts: Considering its smaller model, VMC1160 is generally suitable for processing small and medium-sized parts and can meet the needs of some small and medium-sized machinery manufacturing.

Overall, the VMC1160 vertical machining center has the characteristics of high precision, high efficiency and flexibility in the field of machining, and is suitable for the production of various mechanical parts. It has significant advantages in improving production efficiency, reducing production costs and ensuring processing quality.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды