- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

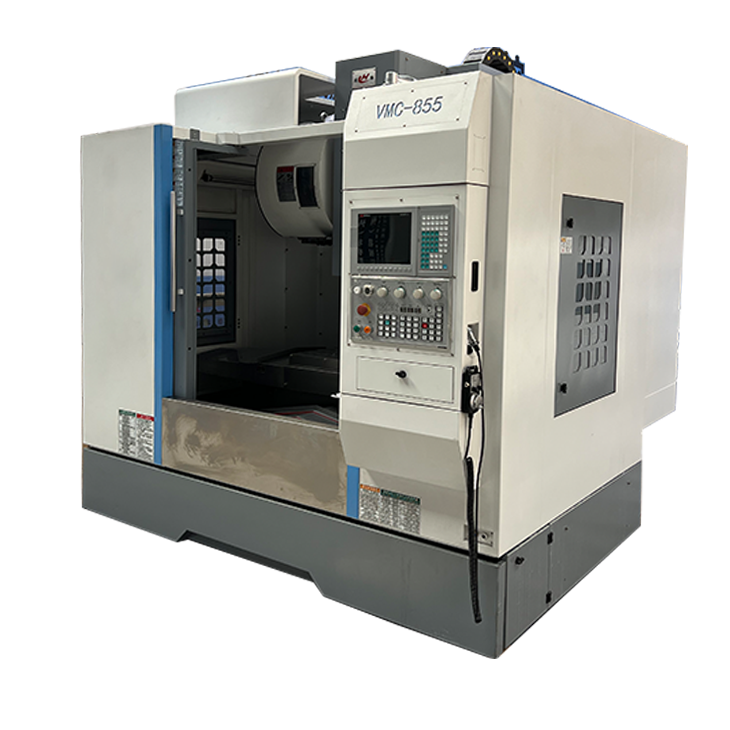

VMC855 fully automated high-precision vertical processing machine tool

VMC855 is a fully automated high-precision vertical machining center with many advantages such as efficiency, accuracy, and stability....

VMC855 is a fully automated high-precision vertical machining center with many advantages such as efficiency, accuracy, and stability.

This machining center is suitable for various molds, engineering machinery, instruments, auto parts, aerospace, electronics, medical equipment and other fields, and can complete parts processing, drilling, tapping, milling and other tasks of various shapes.

The machine tool spindle uses high-precision imported bearings with high stability and high rigidity. The spindle is equipped with a dynamic balancing device and a constant-power spindle motor, which can meet high-speed and high-precision processing requirements.

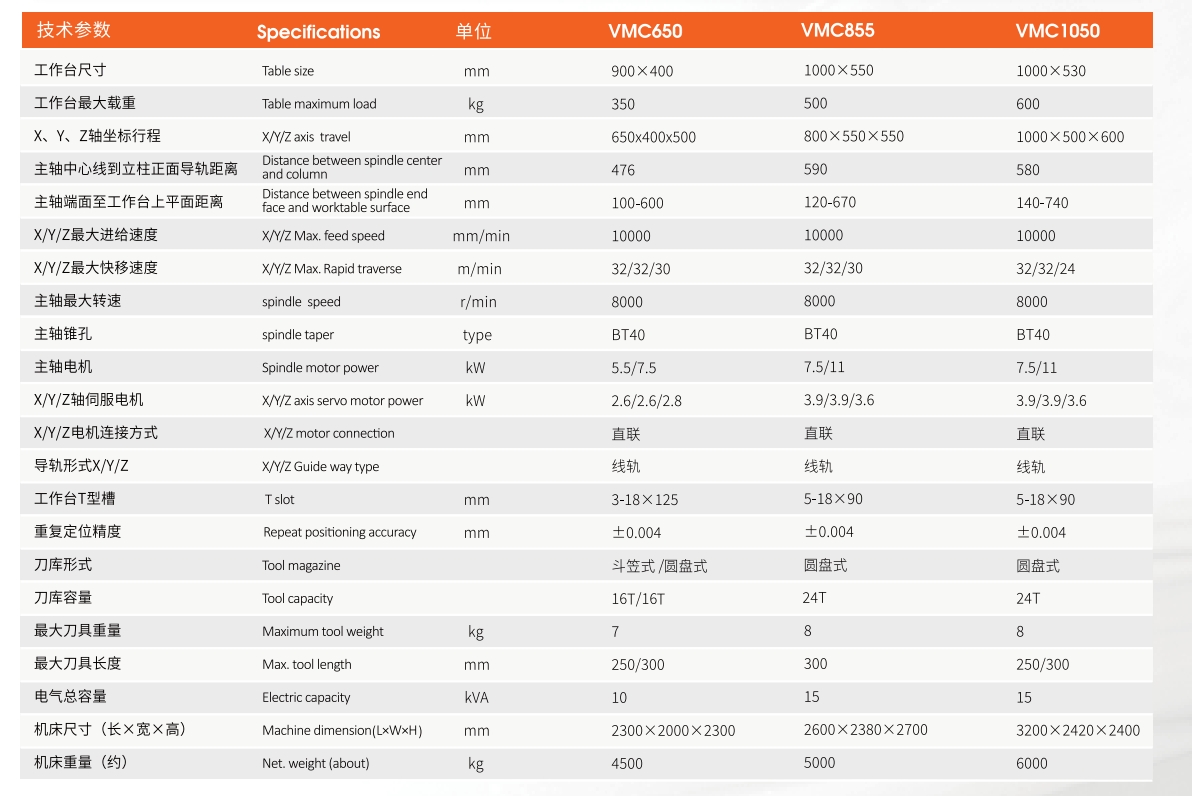

The VMC855 machining center adopts a modular design, with a large workbench area and strong load-bearing capacity, and can withstand the processing of large workpieces. At the same time, it can meet the needs of high-precision processing at different angles and on different planes according to the processing requirements.

The machine tool control system adopts Siemens, Fanuc and other brands and has the characteristics of high reliability, high precision and high flexibility. Users can customize the process flow according to their own processing needs and control various parameters during the processing to ensure processing accuracy and stability.

In addition to high-precision machining functions, the VMC855 machining center also has many features of an automated production line. The machine has a high degree of automation and strong stability. It does not require personnel to operate next to the machine tool, which improves processing efficiency and accuracy. At the same time, it has its own intelligent testing instruments to conduct automated testing of processed products to ensure the quality of processed products.

In short, the VMC855 fully automated high-precision vertical machining center is an efficient, precise and stable machine with a wide range of applications and a variety of advanced features. It is an important piece of equipment in modern manufacturing.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды