- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Automated CNC machining lathe

The automated CNC machining lathe is an advanced machine tool that combines automation and computer numerical control technology and is used to complete the precision machining of workpieces....

The automated CNC machining lathe is an advanced machine tool that combines automation and computer numerical control technology and is used to complete the precision machining of workpieces. Here are some features and functions about automated CNC machining lathes:

1. CNC system: Equipped with a computer numerical control (CNC) system, which allows operators to control the movement, speed and processing path of the tool by writing CNC programs.

2. Automatic tool changing system: It has an automatic tool changing function, which can automatically change tools of different types or sizes during processing, improving the flexibility and efficiency of processing.

3. Automated clamping system: Equipped with an automatic clamping system that can automatically clamp and release workpieces, reducing the need for manual operations and improving production efficiency.

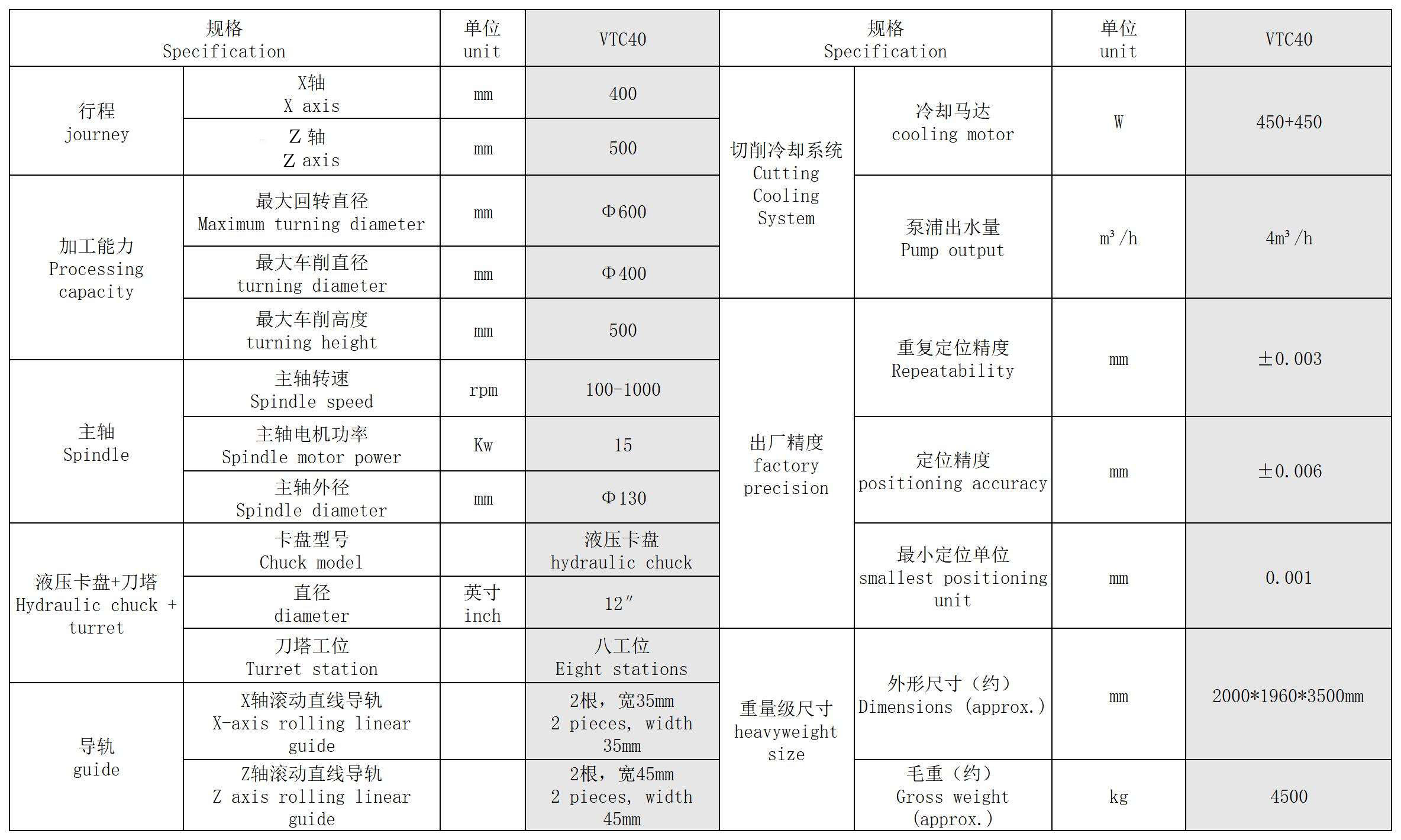

4. Multi-axis control: Usually supports multi-axis control, including X-axis, Y-axis, Z-axis, etc., allowing the machine tool to perform precise movements in multiple directions.

5. Simulation and prediction functions: Some advanced CNC systems may have simulation and prediction functions, allowing the accuracy of the program to be verified before actual machining and predicting possible problems.

6. Intelligent sensing technology: It may include intelligent sensing technology, such as a vision system or sensor network, which is used to monitor workpiece status, tool wear, etc. in real time to make corresponding adjustments.

7. Remote monitoring and diagnosis: Supports remote monitoring, allowing operators to remotely monitor the production process and perform diagnosis. This helps to detect problems promptly and take necessary measures.

8. Data collection and analysis: Collect and analyze data during processing in real time to optimize the production process, improve equipment utilization, and perform predictive maintenance.

9. High-speed drive system: Equipped with a high-speed drive system to achieve fast and accurate tool movement, improving processing speed and overall production efficiency.

10. Safety system: Contains safety functions to ensure the safety of personnel and equipment during operation. This may include emergency stops, safety doors, anti-collision systems, etc.

11. Flexible production: Able to adapt to different types, sizes and shapes of workpieces to achieve flexible production, suitable for small batch and diversified production.

Combining these features and functions, automated CNC machining lathes are designed to increase productivity and reduce manual intervention while ensuring high-precision and high-quality machining. These machine tools are widely used in various fields of manufacturing.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды