- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

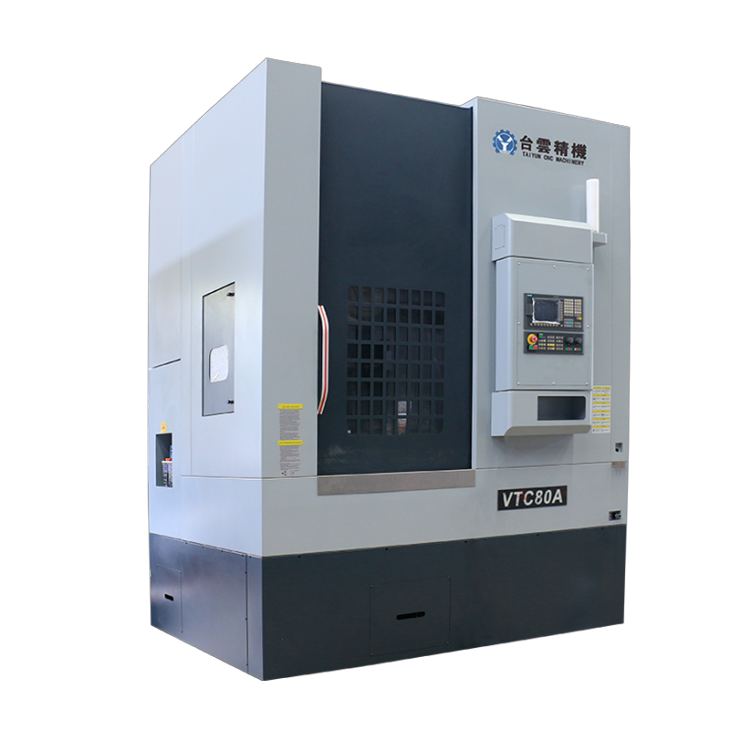

Brake disc CNC vertical lathe

The brake disc CNC vertical lathe is a high-precision CNC machine tool specially designed for brake disc processing....

The brake disc CNC vertical lathe is a high-precision CNC machine tool specially designed for brake disc processing. This machine tool combines the accuracy of CNC technology with the stability of a vertical structure to provide an efficient and accurate solution for brake disc processing. Here are some key features and benefits about brake disc CNC vertical lathes:

1. High-precision processing: As a key automotive component, brake discs require extremely high precision. The CNC vertical lathe adopts an advanced CNC system, which can accurately control the movement trajectory and processing parameters of the tool, ensuring that every size and shape of the brake disc meets the design requirements.

2. Efficient cutting performance: Based on the material and shape characteristics of the brake disc, the spindle and tool system of the CNC vertical lathe are optimized to achieve efficient and stable cutting performance. This not only improves processing efficiency, but also reduces tool wear and production costs.

3. Rigidity and stability: The brake disc CNC vertical lathe adopts an integral casting bed and a heavy-duty design to ensure that the machine tool has excellent rigidity and stability during processing. This helps reduce processing vibration and deformation, and improves processing accuracy and surface quality.

4. Automation and intelligence: Modern brake disc CNC vertical lathes are usually equipped with automation and intelligence functions, such as automatic tool change, automatic measurement, automatic compensation, etc. These functions of CNC vertical lathe can greatly reduce manual intervention, improve processing efficiency, and ensure the stability and consistency of processing quality.

5. Strong adaptability: Brake disc CNC vertical lathes can not only process brake discs of standard specifications, but can also be customized according to customer needs. By changing tools and fixtures, the machine can easily adapt to brake disc processing needs of different sizes and shapes.

In addition, in order to ensure the long-term stable operation and processing quality of CNC vertical lathes, regular maintenance and upkeep are also essential. This includes cleaning machine tools, checking lubrication systems, replacing worn parts, etc. At the same time, operators also need to have rich CNC technology and machine tool operation experience to ensure the smooth progress of the processing process.

In general, brake disc CNC vertical lathes play an important role in the field of brake disc manufacturing due to their high precision, efficiency and stability. With the continuous development of the automobile industry, the requirements for brake disc processing are becoming higher and higher. Therefore, choosing a CNC vertical lathe with excellent performance is of great significance to improve the manufacturing level and market competitiveness of brake discs.

| Specification | unit | VTC80A | Specification | unit | VTC80A |

| X axis | mm | 670 | Turret station | Four stations/eight stations | |

| Z axis | mm | 200-1050 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ1000 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ800 | cooling motor | W | 450+750 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.005 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.008 |

| Spindle diameter | mm | Φ180 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*2100*3600mm | |

| diameter | inch | 24″ | Gross weight (approx.) | kg | 9000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды