- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

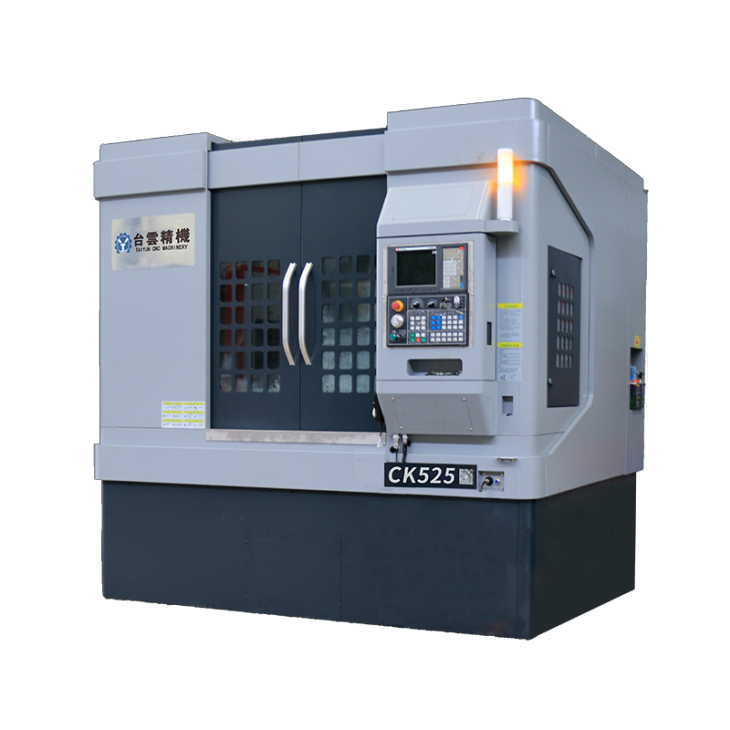

CNC double column vertical lathe

CNC double-column vertical lathe is a kind of lathe, which is a vertical lathe with the characteristics of high precision, high efficiency and good stability....

CNC double-column vertical lathe is a kind of lathe, which is a vertical lathe with the characteristics of high precision, high efficiency and good stability. It is mainly used to process the inner hole, outer circle and end face of larger workpieces. It is especially suitable for precision processing of various high-precision, multi-batch, complex-shaped parts in aviation, aerospace, military, automotive and other industries.

The CNC double-column vertical lathe consists of support components, spindle components, control system, servo system, automatic tool changer, automatic pallet changer system, and auxiliary system. The supporting parts are composed of bed, column and workbench, etc., and are the basic components of the machining center. The spindle speed control device mainly consists of a digital DC speed regulating device and a DC motor. PLC is used for enabling control, and function realization is achieved by controlling the DC motor. In addition, the CNC double-column vertical lathe is also equipped with a multi-station turret tool holder, which has high positioning accuracy and short tool change time. The CNC double-column vertical lathe has a novel appearance design, easy panel operation, and fully enclosed protection. It is suitable for semi-finishing and finishing of small and medium-sized parts.

Machining parts on a CNC double-column vertical lathe is achieved through the relative movement of the tool and the workpiece. During CNC double-column vertical lathe processing, the motion coordinates of the tool and the workpiece are divided into some small unit quantities, that is, small displacement amounts. The CNC device moves the coordinates by several small displacement amounts according to the requirements of the processing program, thereby realizing the tool The relative movement with the workpiece completes the processing of the part.

In general, the CNC double-column vertical lathe has the characteristics of high performance, high precision and low noise, and can meet the processing needs of various complex parts. It is an indispensable and important equipment in modern machinery manufacturing industry.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды