- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

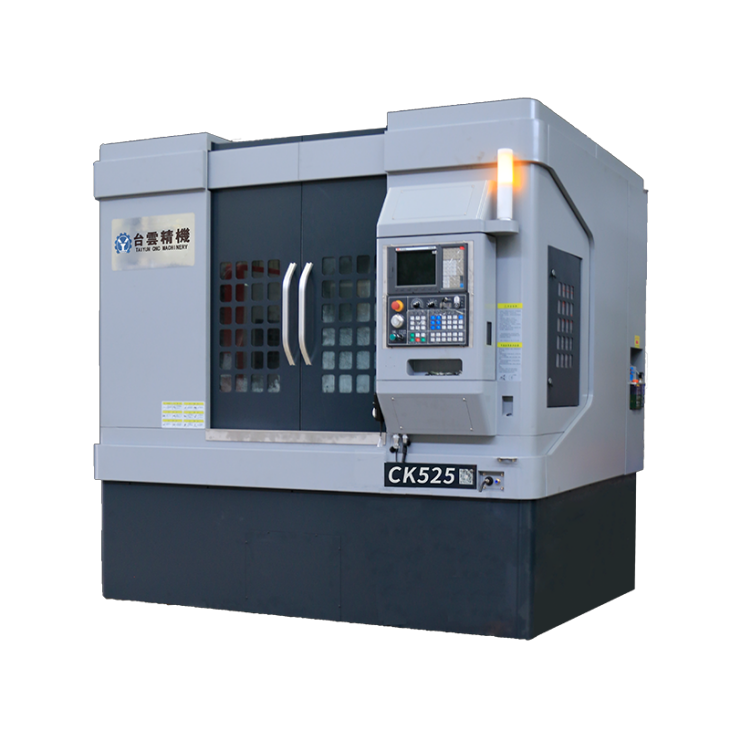

cnc metal lathe

CNC metal lathe is a mechanical equipment used to process metal workpieces. It can control the movement of workpieces and cutting tools through a computer numerical control system to achieve precise machining operations....

CNC metal lathe is a mechanical equipment used to process metal workpieces. It can control the movement of workpieces and cutting tools through a computer numerical control system to achieve precise machining operations. The following is a general introduction to CNC metal lathes:

Structure and working principle:

1. CNC metal lathes usually consist of machine tool main body, CNC system, drive system, workbench, tool rest and other components.

2. The CNC system receives pre-programmed processing instructions and controls the drive system to accurately control the movement trajectories of the workpiece and tool to achieve processing operations.

3. The tool can perform various forms of cutting and processing on the surface of the workpiece.

Features:

1. High precision: The CNC system can accurately control the size and surface quality of the workpiece to ensure that the processing accuracy meets the requirements.

2. Strong flexibility: Different processing programs can be written according to processing needs, and it is suitable for processing workpieces of various complex shapes and sizes.

3. High degree of automation: The processing process can be automatically controlled, reducing manual intervention and improving production efficiency.

4. Versatility: Able to perform a variety of processing operations such as turning, boring, milling, drilling, etc. to meet the processing needs of different workpieces.

5. Programmability: The processing program can be written according to the processing requirements to flexibly cope with various processing tasks.

Application areas:

CNC metal lathes are widely used in machinery manufacturing, aerospace, automobile manufacturing, mold processing and other fields to process various metal parts and workpieces, such as bearing seats, gears, shaft parts, etc.

Operation and safety:

1 Operators need to receive professional training and master the operating skills and safety procedures of the CNC system.

2. During operation, you need to pay attention to safety protection measures, such as wearing protective equipment and avoiding accidents such as collisions and pinches.

The emergence and widespread application of CNC metal lathes has greatly improved the accuracy and efficiency of metal processing and promoted the development of industrial manufacturing.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды