- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

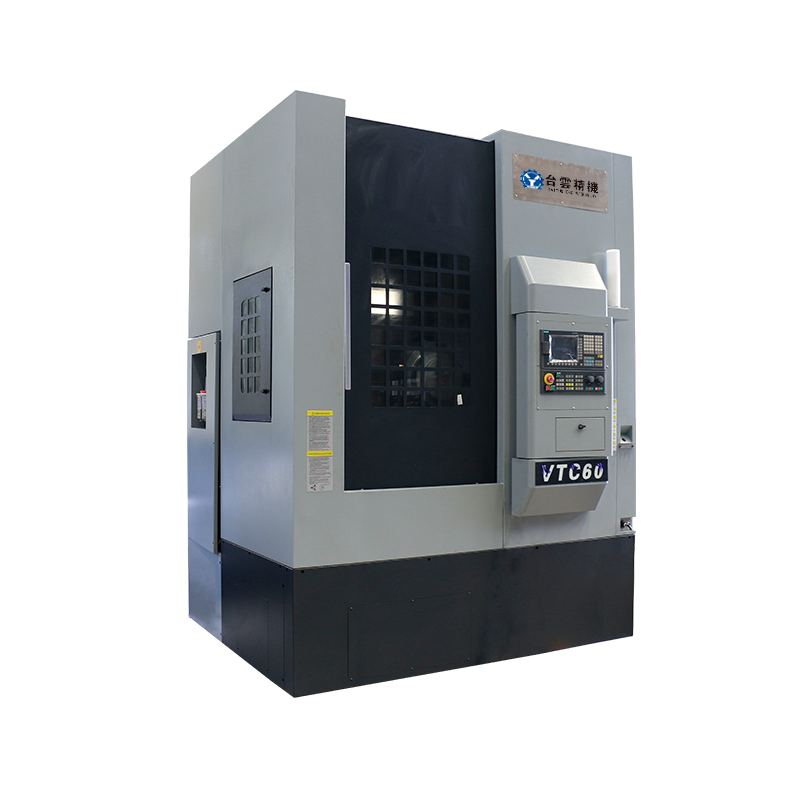

CNC vertical lathe for traction sheave

The traction sheave is an important component of the elevator system. It uses the friction between the traction wire rope and the rope groove on the traction sheave flange to transmit power....

The traction sheave is an important component of the elevator system. It uses the friction between the traction wire rope and the rope groove on the traction sheave flange to transmit power. For the production and processing of traction sheaves, CNC vertical lathe is a very suitable processing equipment.

The CNC vertical lathe for traction sheaves is a highly automated CNC machine tool. It uses a computer program to control the movement of the machine tool to achieve precise processing of the workpiece. CNC vertical lathes have the advantages of high precision, high efficiency, good stability, etc., and are particularly suitable for processing parts of various complex shapes.

As a cylindrical part, the traction sheave has processing requirements including milling, cutting, drilling, etc. The CNC vertical lathe for traction sheaves can easily meet these requirements, and control the movement trajectory of the tool through a computer program to achieve high-precision processing of the traction sheave. At the same time, the CNC vertical lathe has a high degree of automation, which can reduce manual intervention and improve production efficiency.

During the processing of the traction sheave, the CNC vertical lathe can select appropriate processing parameters and tools according to the technical requirements of the traction sheave, such as strength, toughness, wear resistance, impact resistance, etc., to ensure processing quality and precision. In addition, CNC vertical lathes can also make intelligent processing control for factors such as workpiece shape and process complexity, ensuring a high level of guarantee for the processing quality, precision and stability of the workpiece.

In short, using CNC vertical lathes to process traction sheaves is an efficient and precise processing method. Through the high-precision processing and automated control of CNC vertical lathes, the processing quality and precision of traction sheaves can be ensured, and the performance and safety of elevator systems can be improved.

| Specification | unit | VTC60 | Specification | unit | VTC60 |

| X axis | mm | 425 | Turret station | Four stations/eight stations | |

| Z axis | mm | 130-730 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ650 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ600 | cooling motor | W | 450+450 |

| turning height | mm | 600 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 1710*2050*2910mm | |

| diameter | inch | 18″ | Gross weight (approx.) | kg | 7500 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды