- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

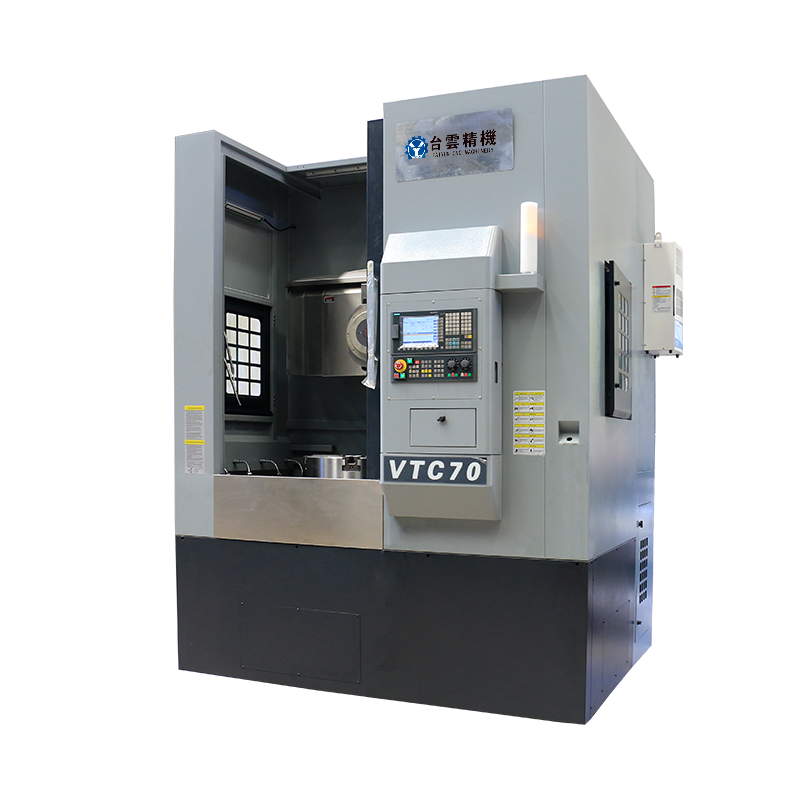

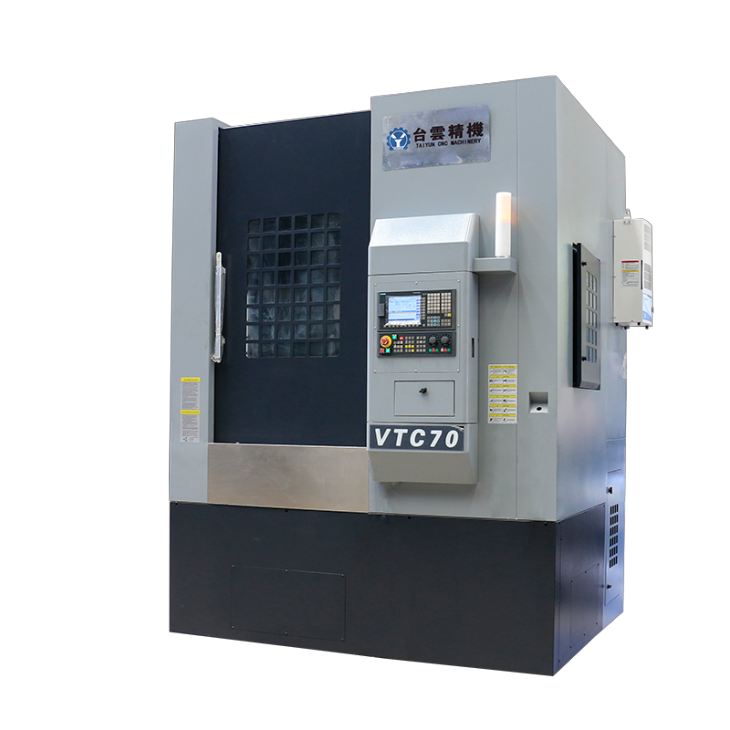

CNC Vertical Lathe Machine for Brake Drums and Discs China

CNC vertical lathe is a kind of equipment specially used for processing brake drums and brake discs. It has the characteristics of high efficiency and high precision....

CNC vertical lathe is a kind of equipment specially used for processing brake drums and brake discs. It has the characteristics of high efficiency and high precision. Brake drums and brake discs are important components in automobile braking systems. They require precision machining to ensure the performance and safety of automobile braking. Here is information about brake drum and brake disc CNC vertical lathes:

1. Structure and features:

CNC vertical lathes usually adopt a vertical structure, with the worktable perpendicular to the spindle, and are suitable for processing round workpieces such as brake drums and brake discs.

Lathes are often equipped with CNC systems that enable complex machining operations and precise cutting control.

Generally, there is an automatic tool changing system, which can automatically change tools of different types or sizes and improve processing efficiency.

2. Processing technology:

The process of machining brake drums and discs typically involves turning, milling, drilling and other operations.

Turning is the main machining process in which the outer and inner diameters of the workpiece are machined to the required size and accuracy by rotating the workpiece and the tool.

Milling is used to machine the surface of the brake disc to give it a specific texture and shape to improve braking performance and heat dissipation.

Drilling is used to process bolt holes or cooling holes on the brake disc for installation and heat dissipation.

3. CNC system:

The CNC system controls the movement of each axis of the lathe and the cutting parameters of the tool, and realizes automated processing through pre-programmed processing programs.

Operators can set processing parameters, processing paths and cutting speeds through the CNC system to achieve precise processing control.

4. Tool selection and cutting parameters:

Brake drums and discs are usually made of cast iron, steel or aluminum alloys, and appropriate tool materials and cutting parameters need to be selected.

Tool materials should be wear-resistant and high-temperature resistant to ensure stable processing over a long period of time.

Cutting parameters include cutting speed, feed speed, cutting depth, etc., which need to be set reasonably according to the workpiece material and processing requirements.

5. Quality control and inspection:

The accuracy with which brake drums and discs are machined is critical to vehicle braking performance, so strict quality control and inspection is required.

The inspection includes the measurement of outer diameter and inner diameter, inspection of surface quality and positioning of holes to ensure that the processed parts meet the design requirements.

6. Safety and Operation:

Operators need to receive professional training to understand the operation and safety procedures of the CNC system to ensure that the operation process is safe and reliable.

Lathes should be equipped with safety protection devices, such as protective covers, emergency stop buttons, etc., to ensure the safety of operators and equipment.

Brake drum and brake disc CNC vertical lathes play an important role in the automobile manufacturing and repair industries, ensuring the performance and safety of automobile braking systems through efficient and precise machining.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды