- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

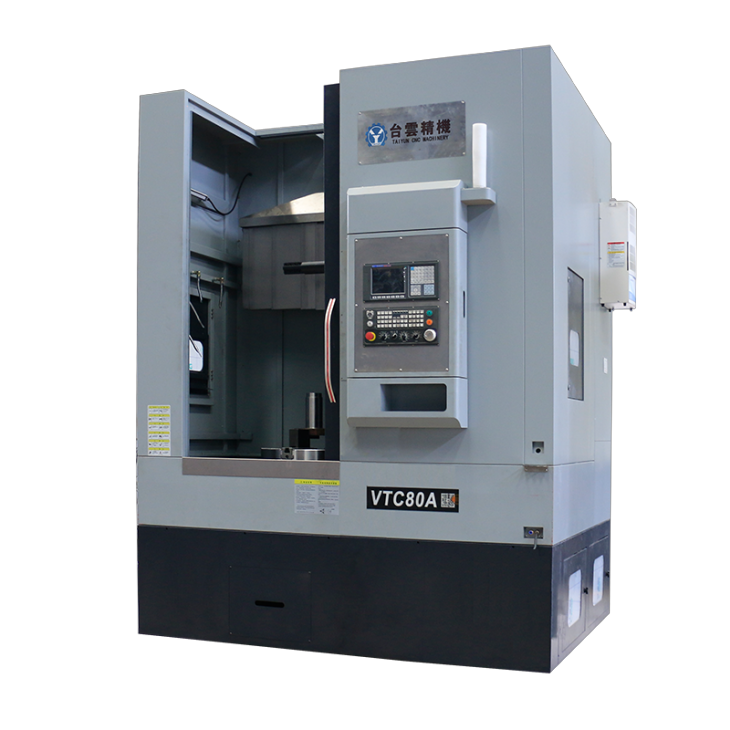

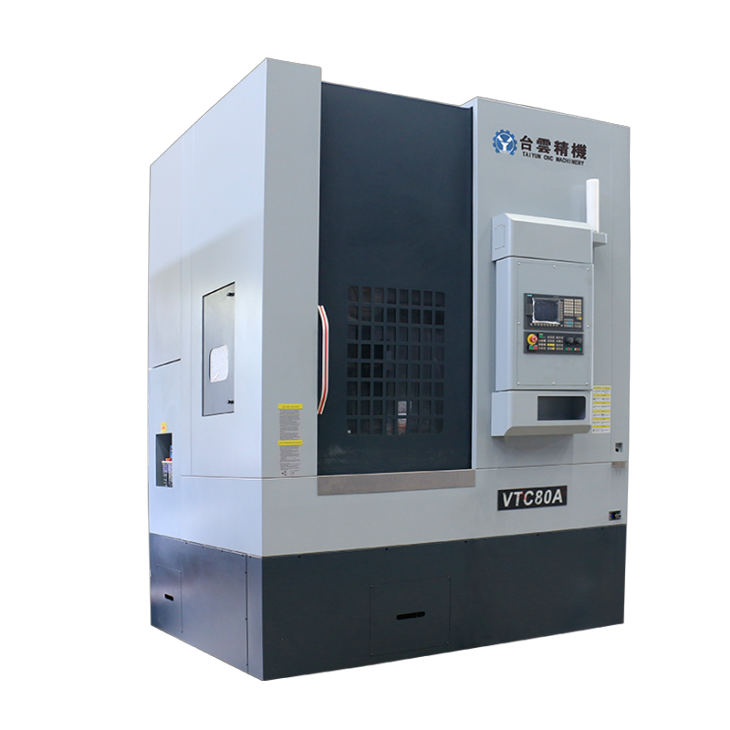

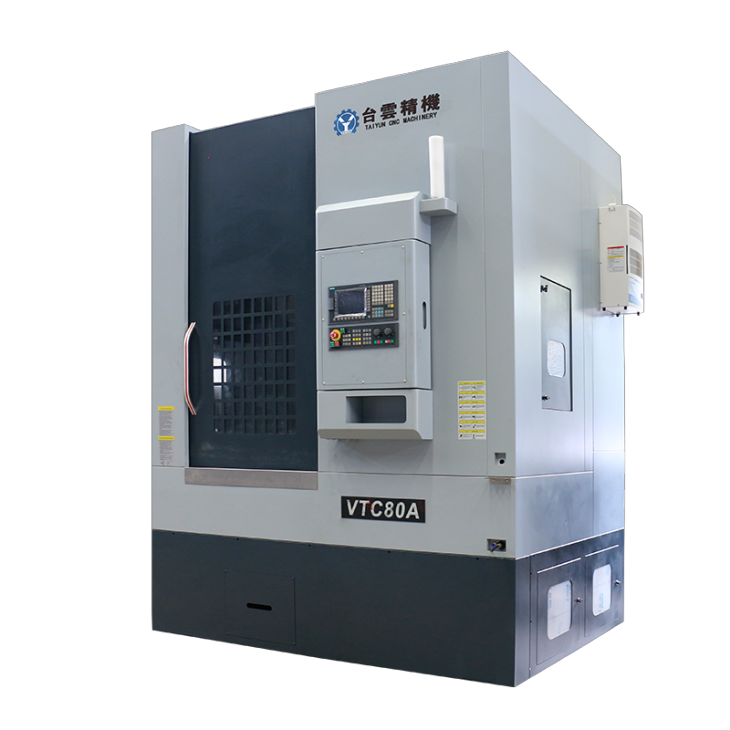

CNC vertical lathe motor housing brake hub special

CNC vertical lathes have unique advantages in processing motor housings and brake hubs....

CNC vertical lathes have unique advantages in processing motor housings and brake hubs. Motor housing brake hubs are usually small and medium-sized parts with complex structures and high precision requirements, which require high-precision processing equipment to complete. The high precision, high rigidity and high stability of CNC vertical lathes make them ideal for processing such parts.

First of all, the high precision of CNC vertical lathes can ensure the processing accuracy of the motor housing brake hub. The high-precision rotation of the CNC vertical lathe spindle and the precise control of the feed system can ensure the dimensional accuracy and surface quality of the parts. In addition, the precise control of the CNC vertical lathe CNC system can achieve precise processing of complex shapes and structures, and the CNC vertical lathe can meet the complex processing requirements of the motor housing brake hub.

Secondly, the high rigidity of CNC vertical lathes can ensure stability during processing. The processing of motor housing brake hubs usually requires large cutting forces and torques, requiring CNC vertical lathes to have sufficient rigidity to resist deformation and vibration. Key components of CNC vertical lathes, such as the bed, column, and spindle box, usually use high-strength materials and advanced structural designs. CNC vertical lathes have excellent rigidity and stability, which can effectively reduce vibration and deformation during processing, ensuring Processing accuracy and stability.

Finally, the high flexibility of the CNC vertical lathe enables it to adapt to the processing of motor housing brake hubs of different specifications and shapes. CNC vertical lathes can easily process parts of different shapes and sizes by replacing tools, fixtures and adjusting CNC programs, improving production efficiency and processing flexibility.

To sum up, CNC vertical lathes are an ideal choice for processing motor housing brake hubs. The high precision, high rigidity and high flexibility of CNC vertical lathes can meet the processing requirements of motor housing brake hubs and ensure processing quality and efficiency. At the same time, CNC vertical lathes can achieve better processing results by optimizing cutting parameters and selecting appropriate tools.

| Specification | unit | VTC80A | Specification | unit | VTC80A |

| X axis | mm | 670 | Turret station | Four stations/eight stations | |

| Z axis | mm | 200-1050 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ1000 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ800 | cooling motor | W | 450+750 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.005 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.008 |

| Spindle diameter | mm | Φ180 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*2100*3600mm | |

| diameter | inch | 24″ | Gross weight (approx.) | kg | 9000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды