- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

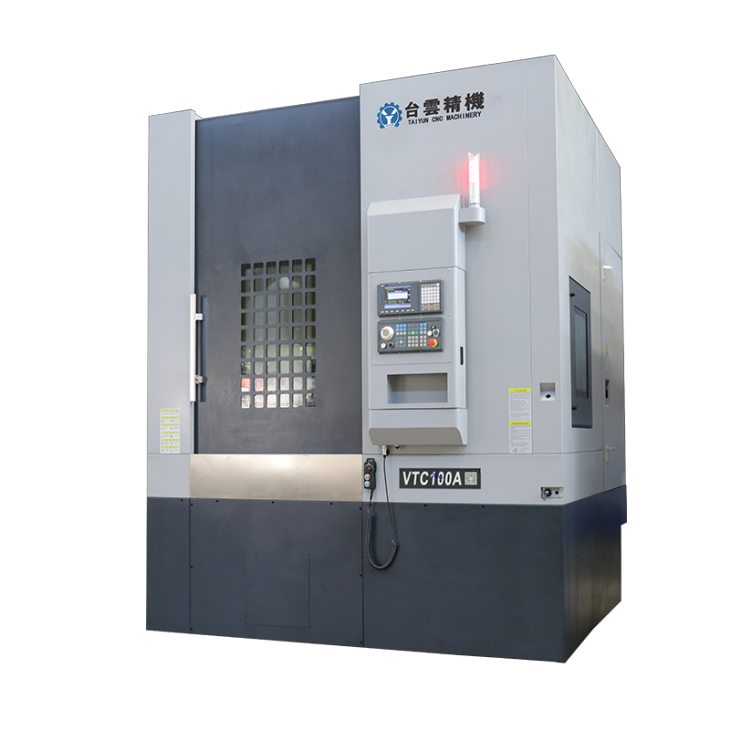

CNC vertical lathe turning is fast and easy to operate

The turning speed of CNC vertical lathe is mainly determined by factors such as workpiece material, tool type, cutting depth, feed speed and spindle speed....

The turning speed of CNC vertical lathe is mainly determined by factors such as workpiece material, tool type, cutting depth, feed speed and spindle speed. High turning speed helps improve production efficiency and processing quality, but it needs to be selected within a reasonable range to avoid problems caused by excessive speed. The following are some factors that affect CNC vertical lathe turning speed:

1. Workpiece material: Different materials for CNC vertical lathe have different hardness and cutting performance, and have different requirements for turning speed. Typically, harder CNC vertical turning materials require lower turning speeds, while softer materials can use higher turning speeds.

2. Tool types: Different types of CNC vertical lathe tools are suitable for different processing tasks, such as rough turning tools, fine turning tools, threading tools, etc. Choosing the right type of tool for CNC vertical turning can help achieve higher turning speeds.

3. Cutting depth: CNC vertical lathe cutting depth refers to the thickness of each cutting tool. Larger cutting depths usually require lower turning speeds to ensure a stable cutting process and avoid excessive cutting heat.

4. Feed speed: CNC vertical lathe feed speed refers to the distance the tool moves on the workpiece per minute. Appropriate feed speed can affect the cutting effect and surface quality. CNC vertical lathe high-speed feed usually requires higher turning speed.

5. Spindle speed: The spindle speed of CNC vertical lathe is an important parameter in CNC vertical lathe. Different spindle speeds are suitable for different types of cutting tasks. CNC vertical lathe high-speed spindle is usually suitable for light load and high-speed cutting.

6. Cooling system: The effective cooling system of CNC vertical lathe can help control the temperature of the cutting area, making higher turning speeds possible. CNC vertical lathe cooling system helps extend tool life and improve machining quality.

When determining the CNC vertical lathe turning speed, cutting tests are usually required to ensure that the processing quality is not affected while maintaining efficient production. At the same time, CNC vertical lathe operators should adjust the turning speed according to the actual situation to ensure a safe and stable processing process.

| Specification | unit | VTC100A | Specification | unit | VTC100A |

| X axis | mm | 850 | Turret station | Four stations | |

| Z axis | mm | 850 | X-axis rolling linear guide | 2 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ1250 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ1200 | cooling motor | W | 750+1200 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 50-800 | Repeatability | mm | ±0.008 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.01 |

| Spindle diameter | mm | Φ200 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2950*2800*3850mm | |

| diameter | inch | Φ1000 | Gross weight (approx.) | KG | 11500 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды