- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

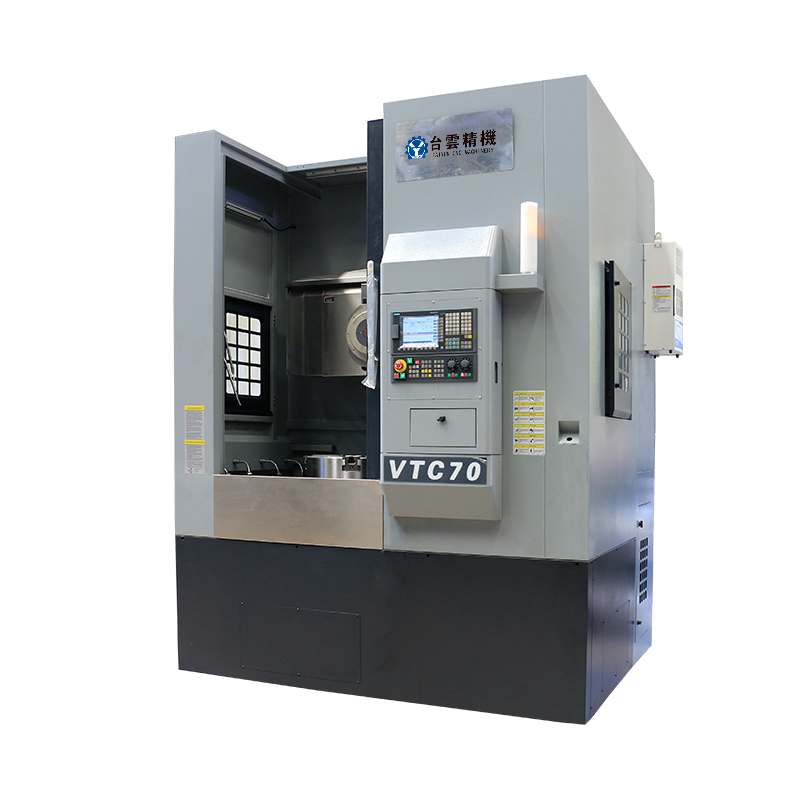

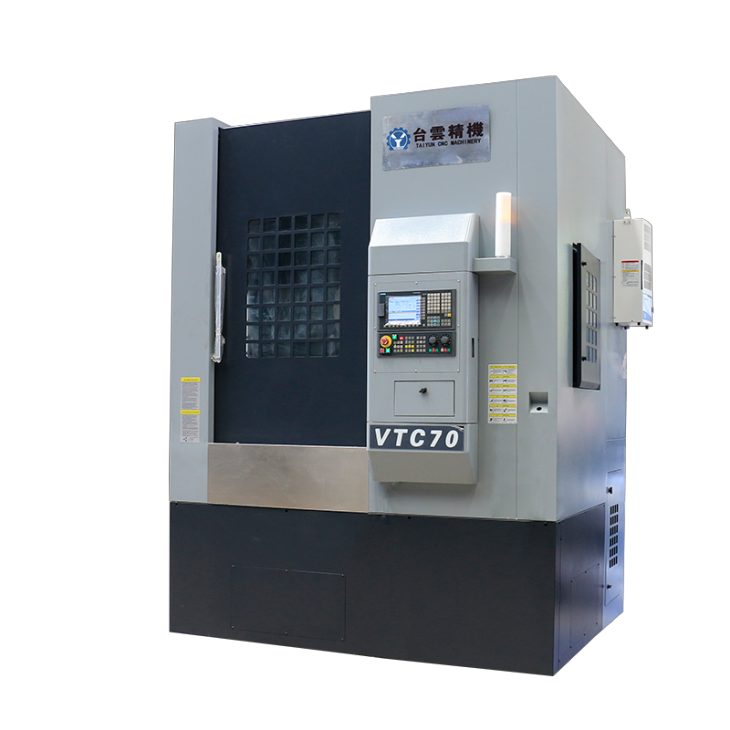

Customized Single Column CNC Lathe

A custom single-column CNC lathe is a CNC machine tool that is custom designed and manufactured for specific machining needs....

A custom single-column CNC lathe is a CNC machine tool that is custom designed and manufactured for specific machining needs. Here are some features and possible customization options for custom single-column CNC lathes in general:

1. Processing range: According to customer needs, the processing range of the customized single-column CNC lathe can be adjusted, including processing dimensions such as diameter, length, height, etc.

2. Tools and tool holders: Different types and specifications of tools and tool holders can be customized according to processing requirements, including turning tools, drilling tools, tapping tools, etc.

3. Workbench: The workbench of a customized single-column CNC lathe can be customized according to needs in terms of processing area, clamping method, load-bearing capacity, etc.

4. CNC system: A suitable CNC system can be selected according to the customer's processing needs, including function-rich CNC systems, high-speed CNC systems, etc.

5. Automation equipment: Automation equipment can be integrated according to customer needs, such as automatic tool changing devices, automatic feeding devices, automatic measuring devices, etc., to improve processing efficiency and accuracy.

6. Structural design: The structural design of single-column CNC lathes can be optimized according to processing requirements, including customization of bed structure, guide rail design, spindle structure, etc.

7. Processing accuracy and stability: Customized single-column CNC lathes need to consider the requirements for processing accuracy and stability, and ensure the processing accuracy and stability of the machine tool through optimized design and material selection.

8. Safety and ergonomics: Customizing single-column CNC lathes requires consideration of the operator's safety and operating comfort, including customization of safety protection devices, operating interface design, etc.

9. Customized service and support: Manufacturers of customized single-column CNC lathes usually provide customized services and after-sales support, including technical consultation, training, maintenance and other support.

Through the above customization options, customized single-column CNC lathes can meet customers' specific processing needs and provide efficient and precise processing solutions.

| Specification | unit | VTC70 | Specification | unit | VTC70 |

| X axis | mm | 700 | Turret station | Four stations/eight stations | |

| Z axis | mm | 130-830 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ800 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ700 | cooling motor | W | 450+750 |

| turning height | mm | 700 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*1800*3200mm | |

| diameter | inch | 21″ | Gross weight (approx.) | kg | 8000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды