- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

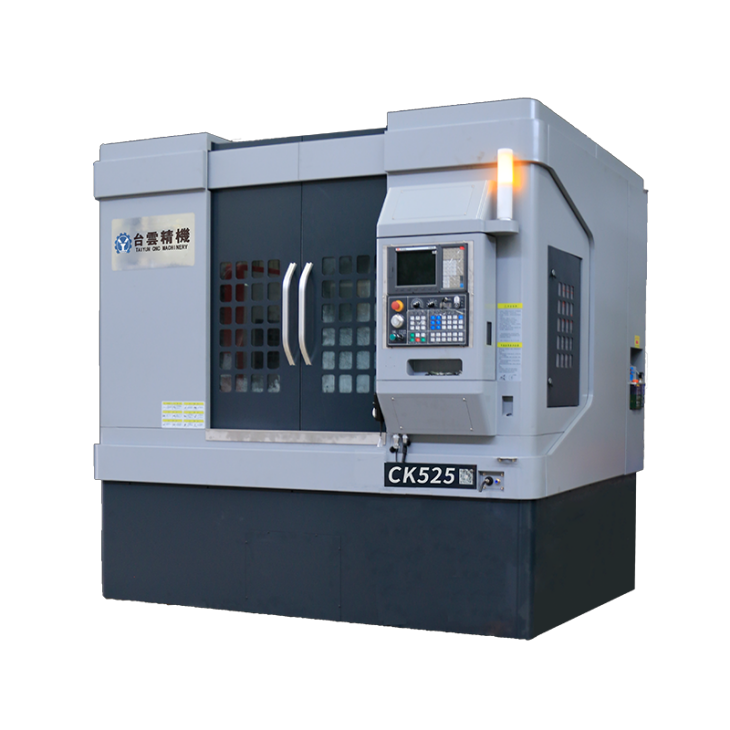

Disc processing CNC vertical lathe

Disk machining is a common processing method on CNC vertical lathes, which is used to process the outer contour, holes, threads, etc. of circular workpieces....

Disk machining is a common processing method on CNC vertical lathes, which is used to process the outer contour, holes, threads, etc. of circular workpieces. The following are the general operating steps of a disc processing CNC vertical lathe:

1. Preparation work: Ensure that the system of the CNC vertical lathe is in normal condition, the work area is clean and tidy, and the safety devices are in good condition. Have the required tools, jigs and workpieces ready.

2. Clamp the workpiece: Use the appropriate clamp of the CNC vertical lathe to clamp the disc-shaped workpiece on the workbench of the CNC vertical lathe to ensure firm and stable clamping.

3. Select tools: The CNC vertical lathe selects appropriate tools according to the processing requirements, such as cutting tools, drill bits, tapping tools, etc., and install them on the tool holder of the CNC vertical lathe.

4. Set the processing program: Load or write the corresponding processing program in the CNC vertical lathe CNC system, set the processing path, cutting parameters, feed speed and other parameters, and make reasonable settings according to the shape of the workpiece and processing requirements.

5. Coordinate setting: Enter the processing coordinates of the workpiece in the CNC vertical lathe CNC system to determine the movement trajectory and position of the tool in each axis to ensure the accuracy and precision of processing.

6. Automatic processing: The CNC vertical lathe starts the processing program, and the CNC vertical lathe will automatically perform processing operations according to the preset processing paths and parameters, including cutting, feeding, tool changing and other actions.

7. Monitoring and adjustment: During the processing process, the CNC vertical lathe promptly monitors the processing status and processing quality, and adjusts the processing parameters or stops processing at any time as needed to ensure the processing quality and workpiece accuracy.

8. Processing is completed and the workpiece is unloaded: After the CNC vertical lathe is completed, the processing program is stopped, the processed workpiece is unloaded from the CNC vertical lathe, and quality inspection and subsequent processing are performed.

9. Cleaning and maintenance: Turn off the CNC vertical lathe CNC system and main power supply, and clean and maintain the CNC vertical lathe and its surroundings, including cleaning the workbench, replacing tools, lubrication systems, etc.

These steps are the general operating procedures for disc machining CNC vertical lathes. The specific operating procedures may vary depending on the equipment model, processing requirements and operating manual requirements.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды