- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

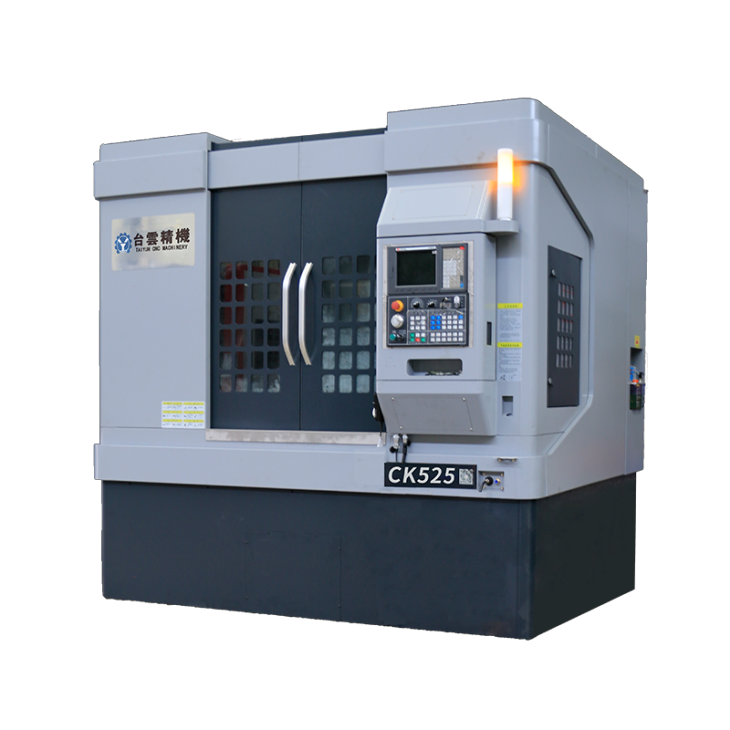

Double tool post digital display vertical lathe

The double-turret digital display vertical lathe is an efficient CNC machine tool with the following features and advantages:...

The double-turret digital display vertical lathe is an efficient CNC machine tool with the following features and advantages:

1. Double tool holder structure: The double tool holder structure increases the stability and rigidity of the machine tool, helps reduce vibration during processing, and improves processing accuracy and surface quality. The double tool post design also makes turning more stable and efficient, and can perform roughing and finishing at the same time, thereby improving processing efficiency.

2. Digital display control system: The double-tool-post digital display vertical lathe is equipped with a digital display control system, which makes the operation easier and enables fast and accurate processing. The digital display system can accurately display processing parameters and axial position, improving the accuracy and consistency of processing.

3. Vertical structure: The spindle of the double-tool-post digital display vertical lathe is perpendicular to the workbench. The vertical structure is conducive to the outflow of processing liquid and improves the processing quality and stability. At the same time, the vertical structure also makes workpiece clamping easier.

4. High rigidity design: The double tool holder digital display vertical lathe adopts a highly rigid machine tool structure and tool holder design, which helps to reduce vibration during processing and improve processing accuracy and surface quality. This design is especially suitable for machining workpieces with strict requirements.

5. Multi-function processing: Double-tool turret digital display vertical lathes are usually equipped with a variety of tools and processing techniques, which can realize different forms of processing operations, including turning, boring, drilling, tapping, etc., and are suitable for processing complex workpieces need.

6. Automated processing: The double-turret digital display vertical lathe is equipped with a CNC system and an automatic tool changer, which can realize automated processing processes, including automatic tool change, automatic feeding, automatic cutting and other functions, to improve production efficiency and consistency.

7. Flexibility: The double-tool-post digital display vertical lathe has flexible processing capabilities and can be quickly adjusted and set according to the requirements of different workpieces, adapting to the needs of multi-variety and small-batch production.

8. Data management: The double-tool post digital display vertical lathe has a data management function, which can realize data collection, monitoring and analysis of the production process, and improve the production management level and production quality.

Double tool post digital display vertical lathe is widely used in the manufacturing industry to process various cylindrical workpieces, such as brake discs, bearing seats, wheel hubs, etc. It is an efficient and precise CNC processing equipment.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды