- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

High Productivity Heavy Cutting Vertical Machining Center

Indispensable for the high efficiency and productivity of modern manufacturing industry is high-precision CNC processing equipment....

Indispensable for the high efficiency and productivity of modern manufacturing industry is high-precision CNC processing equipment. Among these equipment, high-productivity heavy-cutting vertical machining center is a very important processing equipment and is widely used in various complex processing tasks. Let’s introduce the characteristics and advantages of this processing equipment.

1. High-speed and high-precision processing capabilities

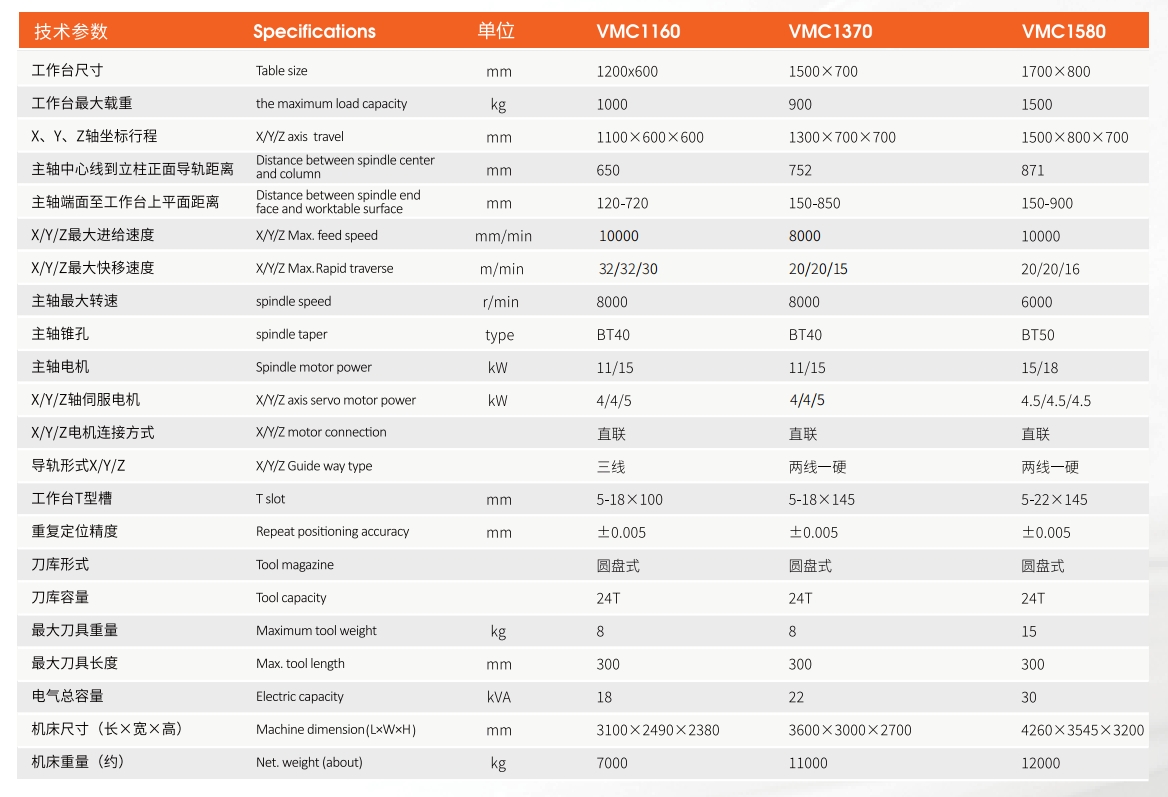

The high-productivity heavy-cutting vertical machining center uses advanced CNC technology and high-precision mechanical structure to achieve high-speed, high-precision cutting. When processing complex curved surface parts, the processing efficiency is significantly improved while ensuring high processing accuracy and repeatability.

2.Multi-stage processing capability

The high-productivity heavy-cutting vertical machining center has multiple processing capabilities such as multi-axis and multi-stage cutting, and can easily complete multi-stage processing of complex parts, greatly improving processing efficiency. At the same time, the machining center is also equipped with an automatic tool changing system and tool magazine, which can easily realize automatic switching of tools, thus avoiding frequent tool changes during processing and improving processing efficiency.

3. Suitable for processing various materials

The high cutting speed and high processing efficiency of the high-productivity heavy-cutting vertical machining center make it suitable for processing various materials, such as stainless steel, titanium alloy, cast iron and other materials. At the same time, the cutting tools and cutting heads of the machining center are also equipped with special coating technology to improve cutting life and cutting quality.

4. Intelligent operating system

The operating system of the high-productivity heavy-cutting vertical machining center adopts intelligent control technology, which can realize automated control and monitoring, allowing operators to operate and manage the machining center more easily. At the same time, the operating system also has functions such as automatic tool detection, automatic compensation and automatic adjustment, which can achieve good automated production.

In short, the high-productivity heavy-cutting vertical machining center is a high-efficiency, high-precision, and multi-functional processing equipment that is widely used in the processing of various complex parts. With the continuous development of manufacturing industry and the continuous advancement of technology, high-productivity heavy-cutting vertical machining centers will play an increasingly important role in the future production process.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды