- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

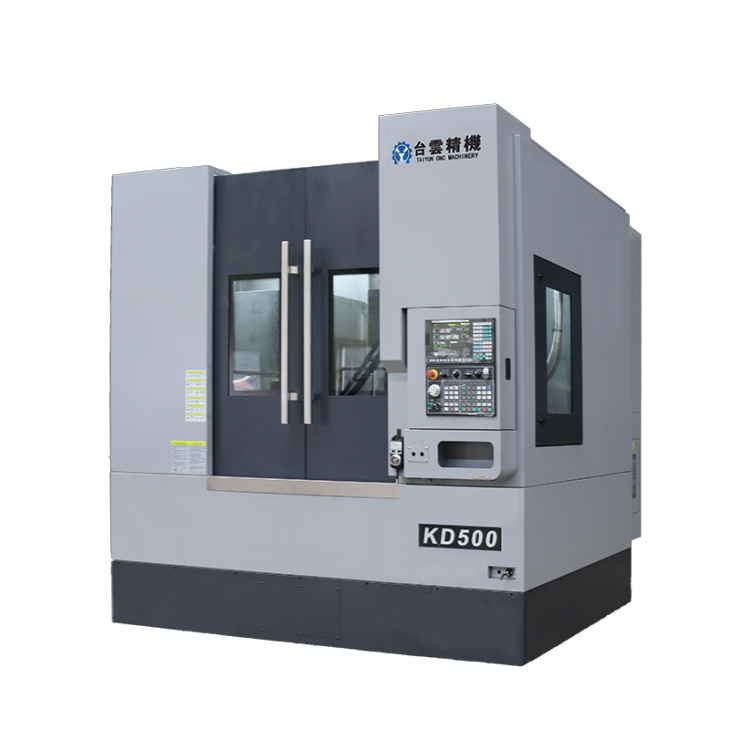

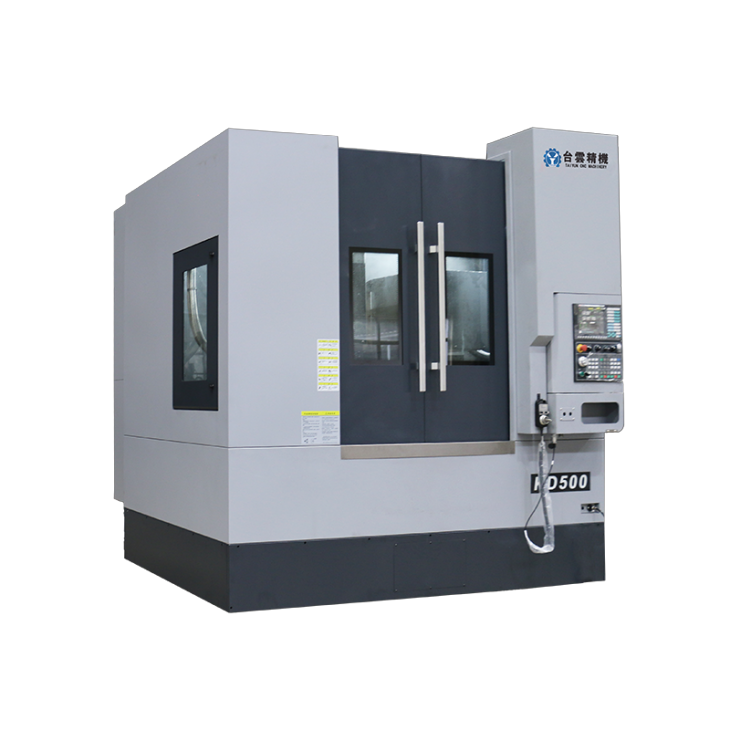

High speed double column lathe

The double-column vertical lathe is a high-precision and high-efficiency machine tool....

The double-column vertical lathe is a high-precision and high-efficiency machine tool. In terms of high-speed machining, the double-column vertical lathe has the following characteristics:

1. High-speed spindle: The spindle of the double-column vertical lathe is usually designed with a high speed, which can achieve high-speed cutting. The high-speed spindle of the double-column vertical lathe can reduce cutting time, improve machining efficiency, and help achieve better machining surface quality.

2. Servo motor control: The feed system of the double-column vertical lathe is usually controlled by a servo motor, which can achieve high-speed, high-efficiency and high-precision machining. The servo motor has the advantages of fast response speed and high control accuracy, which can meet the needs of high-speed machining.

3. The contact area between the tool and the workpiece is large: Due to the design characteristics of the double-column vertical lathe, the contact area between the tool and the workpiece is larger, which is conducive to reducing tool wear and improving machining efficiency. At the same time, the large contact area is also conducive to achieving a more stable cutting process.

4. Efficient cutting parameter setting: The double-column vertical lathe can set multiple cutting parameters, optimize the cutting parameters according to factors such as the material, shape and machining requirements of the workpiece, and achieve efficient machining.

During high-speed machining of double-column vertical lathes, the following points should be noted:

1. Control of cutting force: When the double-column vertical lathe is cutting at high speed, the cutting force will increase. It is necessary to reasonably control the cutting amount to avoid excessive cutting force causing damage to the machine tool and workpiece.

2. Control of cutting heat: When the double-column vertical lathe is cutting at high speed, the cutting heat will rise rapidly. Appropriate measures need to be taken for cooling to avoid thermal deformation of the workpiece and tool wear.

3. Guarantee of machining accuracy: When the double-column vertical lathe is machining at high speed, it is necessary to ensure the accuracy and stability of the machine tool, as well as the positioning and clamping accuracy of the workpiece to ensure machining accuracy.

In short, as a high-precision and high-efficiency machine tool equipment, the double-column vertical lathe has good performance and application prospects in high-speed machining. During use, it is necessary to pay attention to issues such as cutting force control, cutting heat control and machining accuracy guarantee.

| Specification | unit | KD500 | Specification | unit | KD500 |

| X axis | mm | 300 | Turret station | Eight stations + eight stations | |

| Z axis | mm | 500 | X-axis rolling linear guide | 3 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ650 | Z axis rolling linear guide | 4 pieces, width 55mm | |

| turning diameter | mm | Φ500 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 30 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2800*2400*2910mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 10000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды