- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

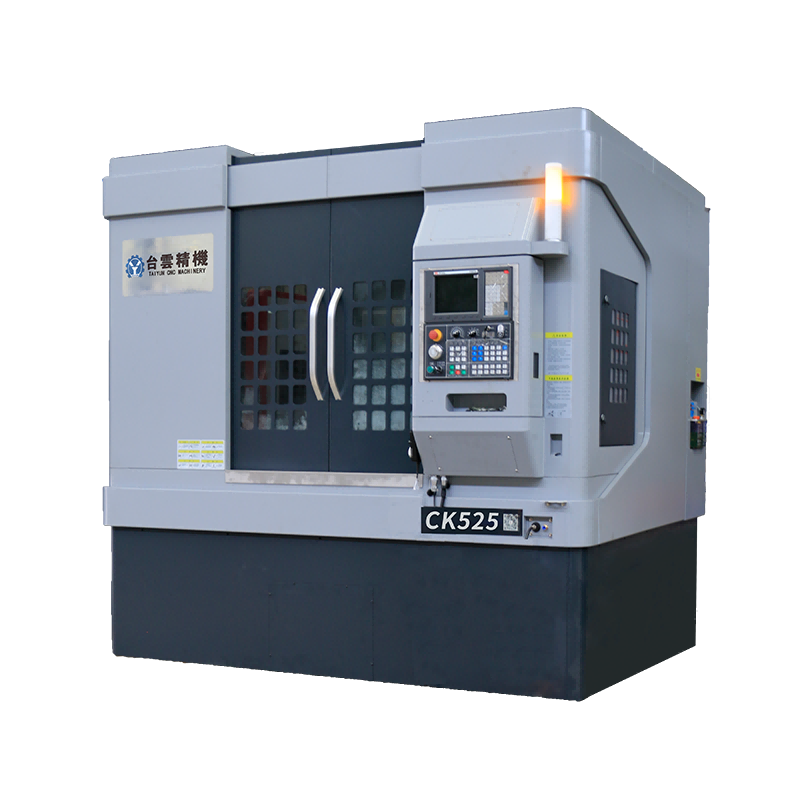

Machining CNC lathe

Machining CNC lathe plays an important role in various industries with its efficient, precise and flexible processing capabilities....

Machining CNC lathe plays an important role in various industries with its efficient, precise and flexible processing capabilities.

1. Principles and advantages of CNC lathes

Machining CNC lathe is an automated machine tool controlled by a computer. Compared with traditional lathes, it has the following advantages:

High precision: Machining CNC lathe adopts an advanced control system, which can achieve more precise processing and ensure product quality and accuracy.

High efficiency: CNC lathes have the function of continuous and automatic processing, saving labor and improving production efficiency.

Strong flexibility: The processing program of CNC lathe can be flexibly adjusted and modified to adapt to the processing requirements of different products.

2. Application fields of CNC lathes

CNC lathes are widely used in various manufacturing industries, covering machinery, automobiles, aerospace, electronics and other fields.

Machinery manufacturing industry: CNC lathes play an important role in the machinery manufacturing industry and are used to process components, bearings, gears and other devices.

Automobile manufacturing industry: The automobile industry has high requirements for product accuracy and quality. CNC lathes can meet these requirements and are used to manufacture engine parts, chassis and body structures, etc.

Aerospace industry: Machining CNC lathe The aerospace industry has extremely high precision requirements for parts, and CNC lathes play an important role in manufacturing engine parts, turbine blades, etc.

Electronic manufacturing industry: CNC lathes are used to process electronic components, connectors, integrated circuits, etc., ensuring the accuracy and stability of products.

3. Development Trend of CNC Lathes

With the continuous advancement of science and technology and the development of manufacturing industry, CNC lathes are developing towards higher precision, higher efficiency and more functions.

Intelligence: With the rapid development of artificial intelligence technology, CNC lathes will achieve intelligent operation and independent learning capabilities, improving production efficiency and quality management levels.

High speed: CNC lathes will achieve higher rotation speeds and processing speeds, significantly shorten processing time, and improve production efficiency.

Multi-functionality: Future CNC lathes will have a variety of processing functions, allowing one machine to be used for multiple purposes, improving production flexibility and efficiency.

High precision: Machining CNC lathe In the field of precision machining, CNC lathes will achieve higher machining accuracy and meet increasingly higher precision requirements.

To sum up, CNC lathes have broad application prospects and development space. Through continuous innovation and technological progress, CNC lathes will surely become a shining star in the field of mechanical processing.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды