- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Metal workpiece processing vertical lathe

A vertical lathe is a common metal processing machine tool with its spindle in the vertical direction and the workpiece fixed on the workbench for processing....

A vertical lathe is a common metal processing machine tool with its spindle in the vertical direction and the workpiece fixed on the workbench for processing. Here is some general information and features about vertical lathes for metal workpiece processing:

1. Structural features: The spindle of a vertical lathe is placed vertically, usually on the top of the bed. The workpiece is mounted on the workbench, while the cutting tool moves on the spindle to complete the machining. This structure makes the vertical lathe suitable for processing larger and smaller workpieces.

2. Processing scope: Vertical lathes are usually used to process larger diameter workpieces, such as shaft parts, gears, threads, etc. Due to its vertical placement of the spindle, the processing length may be limited, but the processing diameter is usually larger.

3. Cutting stability: Since the workpiece is fixed on the workbench, the stability during the cutting process is high. This helps ensure machining accuracy and surface quality.

4. Processing accuracy: Vertical lathes can achieve high processing accuracy, especially for the processing of shaft parts. High-precision machining can be achieved by precisely controlling the movement of the cutting tool in the vertical direction.

5. Applicable materials: Vertical lathes are suitable for processing various metal materials, including steel, iron, aluminum, copper, etc. They are often used to machine large parts such as ship components, wind turbine parts, etc.

6. Tool system: Vertical lathes are usually equipped with various cutting tools, including turning tools, drill bits, boring tools, etc. The choice of tool system depends on the machining requirements and workpiece material.

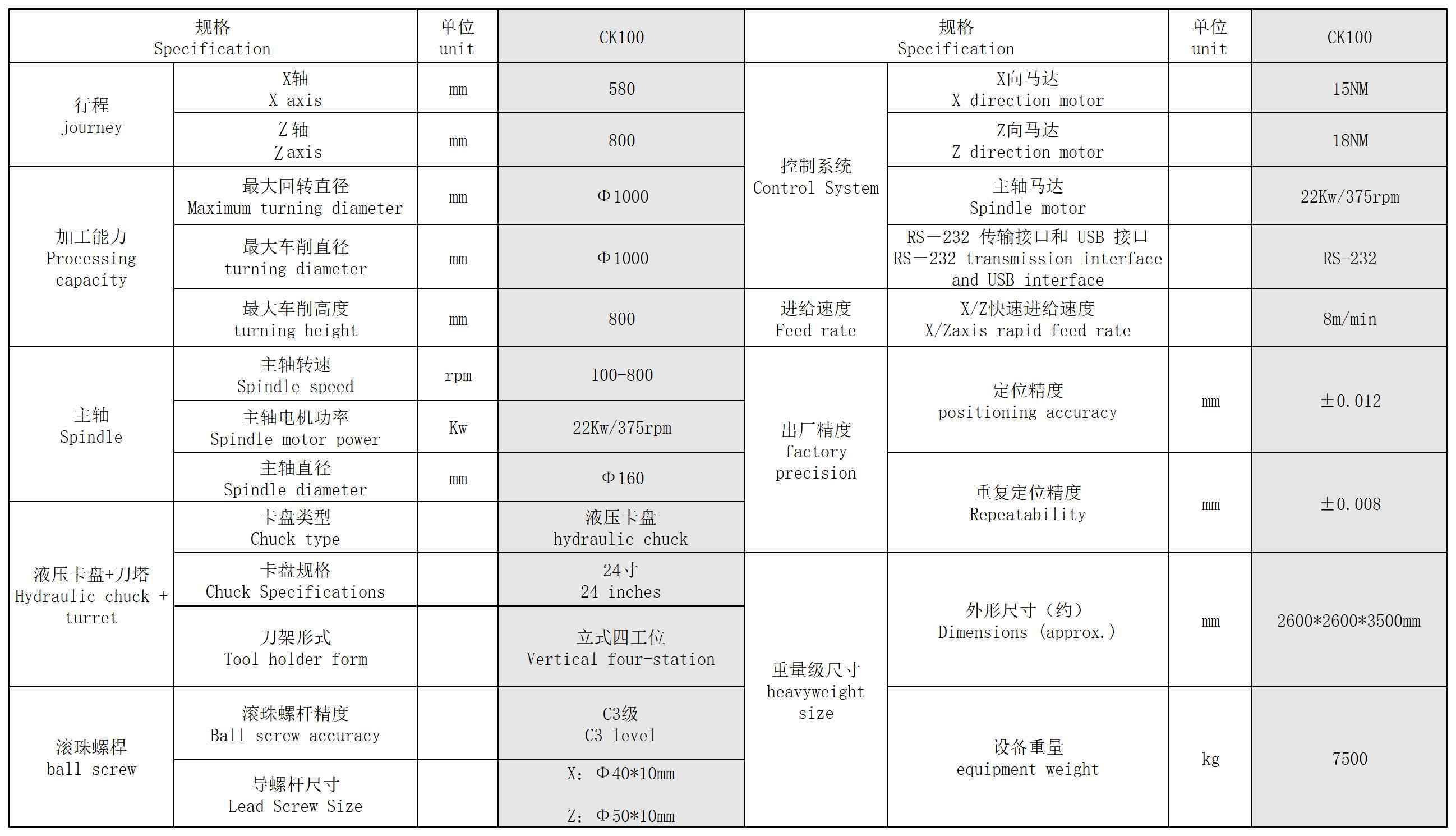

7. CNC system: Modern vertical lathes are usually equipped with CNC systems, which can achieve precise machining operations and complex contour processing. CNC systems can also improve production efficiency and processing consistency.

8. Safety: When using a vertical lathe, operators need to pay attention to safety matters, especially when operating large workpieces. Appropriate safety measures include safety guards, emergency stop buttons, etc.

In general, a vertical lathe is a commonly used metal processing machine tool that is particularly suitable for processing large diameter workpieces. They usually have the characteristics of high precision, good stability and high processing efficiency, and play an important role in the manufacturing industry.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды