- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Parts processing vertical structural lathe

A vertical CNC lathe is a machine tool used to process parts. Its working method is to control the movement of the tool on multiple axes through a CNC system to complete the precise processing of the workpiece....

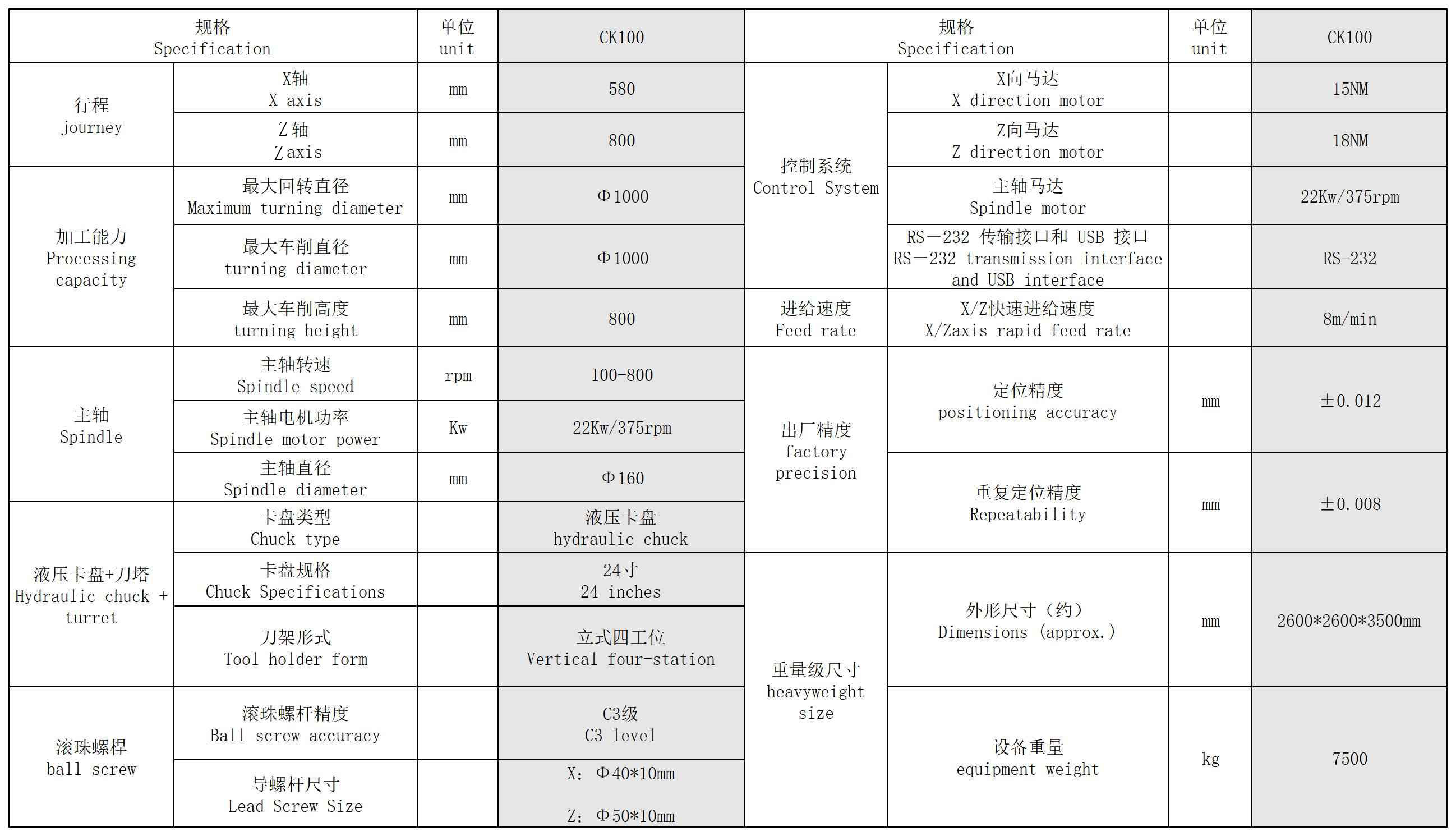

A vertical CNC lathe is a machine tool used to process parts. Its working method is to control the movement of the tool on multiple axes through a CNC system to complete the precise processing of the workpiece. The following is general information about vertical CNC lathes for component processing:

1. Structure and working principle:

Vertical CNC lathes usually include spindles, turrets, worktables, guide rails, etc.

The spindle is responsible for rotating the workpiece, while the turret is responsible for moving the tool in different directions to achieve multi-axis machining.

The CNC system controls the movement of the tool through pre-programmed instructions to achieve precise cutting of the workpiece.

2. Multi-axis control:

This multi-axis control enables lathes to perform complex cutting and machining operations, improving processing flexibility and precision.

3. CNC system:

The CNC system is the core of the vertical CNC lathe and is responsible for interpreting and executing pre-written machining programs.

These programs include parameters such as tool path, cutting speed, feed speed, etc., and control the movement of the tool through these instructions.

4. Automatic tool changing system:

In order to improve production efficiency, some vertical CNC lathes are equipped with automatic tool changing systems, which can automatically change different types or sizes of tools.

Automatic tool changing systems can reduce downtime and increase production continuity.

5. Tools and cutting process:

Tool selection and cutting parameter settings are crucial for component processing.

Different cutting processes (such as turning, boring, milling, etc.) require different types of tools and machining strategies.

6. Safety and Operation:

Operators need to be trained to understand the operation and programming of CNC systems.

Safety measures include machine tool fixation, cutting fluid treatment, emergency stopping devices, etc. to ensure the safety of operators and machine tools.

7. Quality Control and Precision:

Vertical CNC lathes are usually used for high-precision machining of workpieces and require regular inspection and calibration to ensure the quality and accuracy of the machining.

Vertical CNC lathes are widely used in the manufacturing industry, especially for high-precision processing of complex parts, such as aerospace, automobile manufacturing and other fields. During use, regular maintenance and upkeep are also crucial to ensuring the normal operation and long life of the machine tool.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды