- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

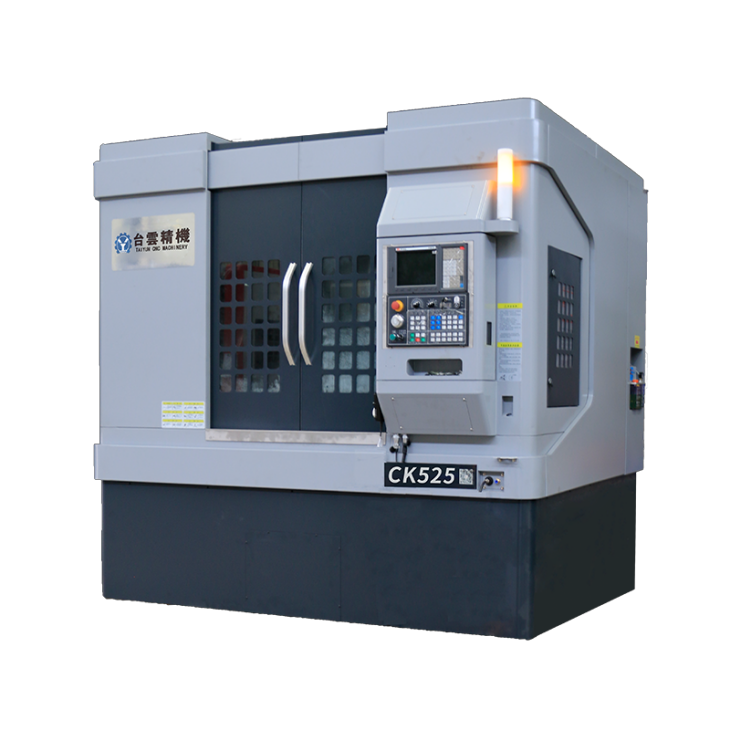

Precision heavy-duty CNC lathe

The precision heavy-duty CNC lathe is a CNC lathe specially used to process large, heavy, and complex parts and has high-precision processing capabilities....

The precision heavy-duty CNC lathe is a CNC lathe specially used to process large, heavy, and complex parts and has high-precision processing capabilities. The following are the features and functions of this type of CNC lathe:

1. High-precision processing: Precision heavy-duty CNC lathes have sophisticated CNC systems, high-precision spindles and motion systems, which can achieve high-precision processing of workpieces, including precise control of shape, size and surface quality.

2. Large workpiece processing capabilities: This type of CNC lathe usually has a large processing range and workbench size, and can process large and heavy workpieces, such as aerospace engine parts, ship parts, automobile engine parts, etc.

3. High-rigidity structure: The precision heavy-duty CNC lathe adopts high-strength and high-rigidity machine tool structure design and is manufactured with high-quality materials. It can withstand large cutting forces and processing loads, ensuring the stability and accuracy of the precision heavy-duty CNC lathe processing process.

4. Powerful cutting capacity: This type of CNC lathe is equipped with a powerful spindle and power system, which can provide sufficient cutting capacity and speed range, and is suitable for efficient processing of various materials.

5. Multi-functional processing: Precision heavy-duty CNC lathes usually have functions such as multi-axis, multi-tool and automatic tool changing systems. Precision heavy-duty CNC lathes can realize multi-faceted processing and multi-process processing of complex workpieces, improving production efficiency and processing accuracy.

6. Intelligent control: Precision heavy-duty CNC lathes are equipped with CNC systems, such as automated processing procedures, automatic tool path optimization and other functions, to improve processing efficiency and operational convenience.

7. Programmable processing: The precision heavy-duty CNC lathe is equipped with a CNC programming system, which is easy to operate and can write processing programs according to different processing requirements to achieve precision processing of complex workpieces.

In summary, precision heavy-duty CNC lathes have the characteristics of high precision, large workpiece processing capabilities, high rigidity structure, strong cutting capabilities, multi-functional processing, intelligent control and programmable processing, and are used for processing large, heavy, and precision parts. one of the important equipment.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды