- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

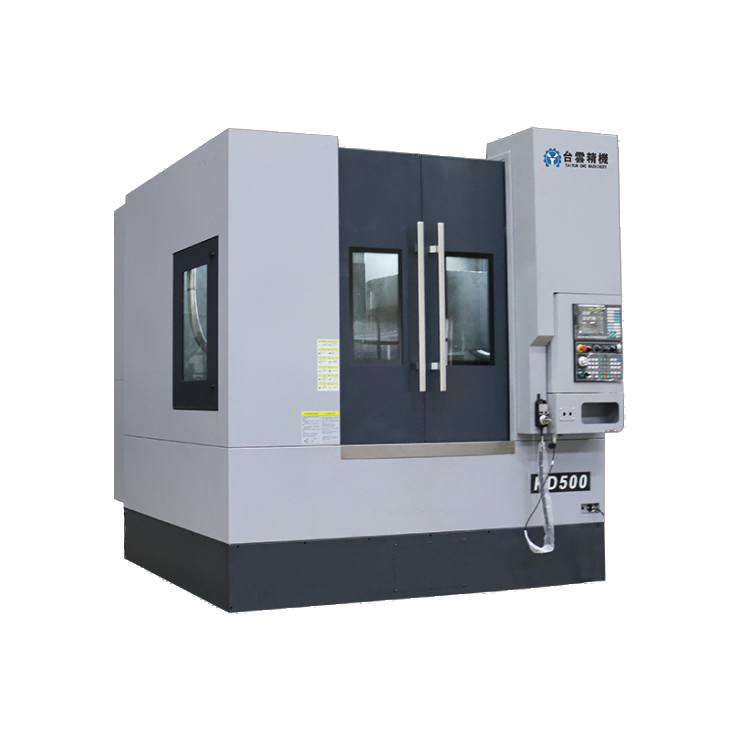

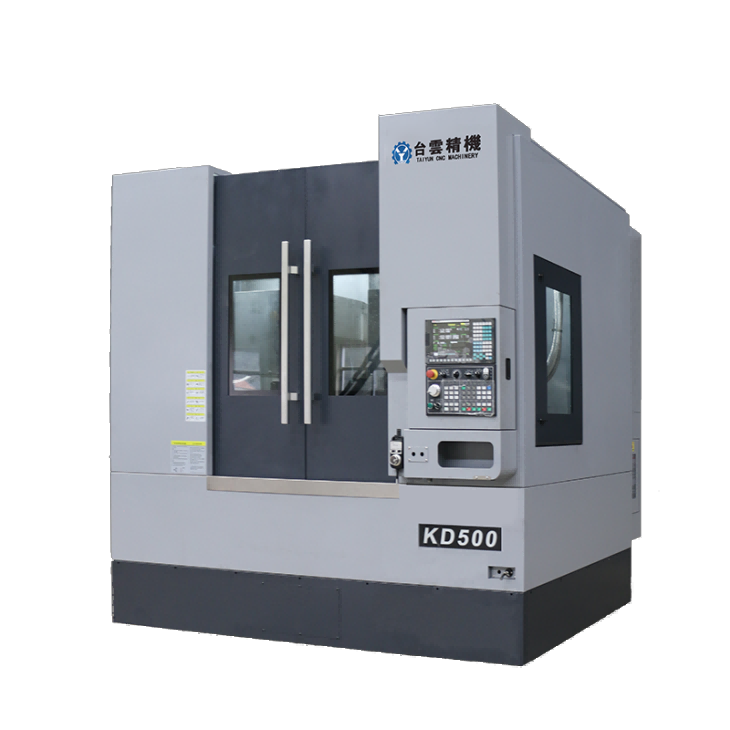

Precision protection CNC vertical lathe

The precision protection CNC vertical lathe is an advanced machine tool that combines high-precision processing capabilities with all-round protection functions....

The precision protection CNC vertical lathe is an advanced machine tool that combines high-precision processing capabilities with all-round protection functions. Precision protection CNC vertical lathes not only have the basic characteristics of CNC vertical lathes, such as high degree of automation, high processing accuracy, high processing efficiency, etc., but also ensure the stability and accuracy of the machine tool during the processing process through precision protection design, while reducing external Environmental impact on machine tools.

Precision protection CNC vertical lathes usually adopt highly rigid bed and column structures to ensure the stability of the machine tool during processing. At the same time, the key components of precision-protected CNC vertical lathes, such as spindles, guide rails, etc., have undergone precision processing and strict quality control to ensure processing accuracy and machine tool reliability.

In terms of protection design for precision protection CNC vertical lathes, precision protection CNC vertical lathes usually adopt a closed protection structure, which effectively prevents cutting fluid, iron filings and other debris from entering the inside of the machine tool, thereby reducing the machine tool's failure rate and maintenance costs. In addition, the precision protection CNC vertical lathe is also equipped with an efficient cooling system and chip removal device to ensure that the machine tool can maintain a constant temperature and a good working environment during the processing process.

In addition, the precision protection CNC vertical lathe also has an intelligent control system and rich processing functions. The control system can accurately control the movement and cutting parameters of the machine tool to achieve efficient and stable processing. At the same time, the precision protection CNC vertical lathe also supports a variety of processing modes and processes, which can meet the processing needs of different workpieces.

In general, the precision protection CNC vertical lathe is an advanced machine tool that integrates high-precision processing, high protection and high intelligence. Precision protection CNC vertical lathes have broad application prospects in aviation, aerospace, automobiles, molds and other fields, and can provide efficient, accurate and reliable processing solutions for these fields.

| Specification | unit | KD500 | Specification | unit | KD500 |

| X axis | mm | 300 | Turret station | Eight stations + eight stations | |

| Z axis | mm | 500 | X-axis rolling linear guide | 3 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ650 | Z axis rolling linear guide | 4 pieces, width 55mm | |

| turning diameter | mm | Φ500 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 30 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2800*2400*2910mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 10000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды