- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

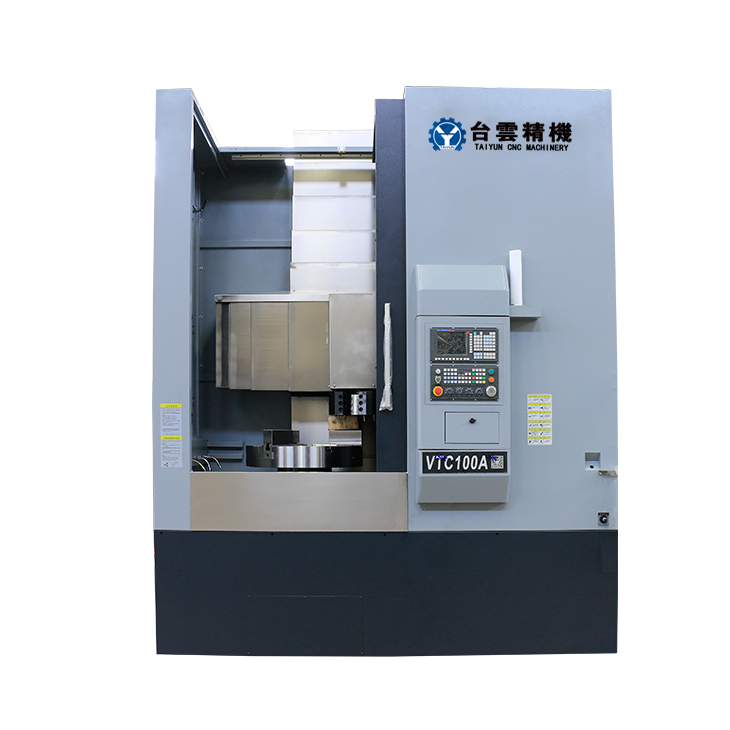

Small single-column vertical lathe for large processing diameters and easy operation

The CNC vertical lathe is a small single-column vertical lathe, which is characterized by large processing diameter and simple operation....

The CNC vertical lathe is a small single-column vertical lathe, which is characterized by large processing diameter and simple operation. This product is suitable for a wide variety of parts and can meet different processing needs. CNC vertical lathes are widely used and involve CNC machining, turning, drilling, milling and other processes. The device has a compact structure and takes up little space, making it ideal for use in small businesses or manufacturing workshops.

The CNC vertical lathe is controlled by a CNC system, with high-precision position control and speed control. It is easy to operate and easy to learn, making it very suitable for beginners and intermediate users. The CNC system can not only store and manage a variety of processing programs, but also can automatically change tools and process, improving production efficiency.

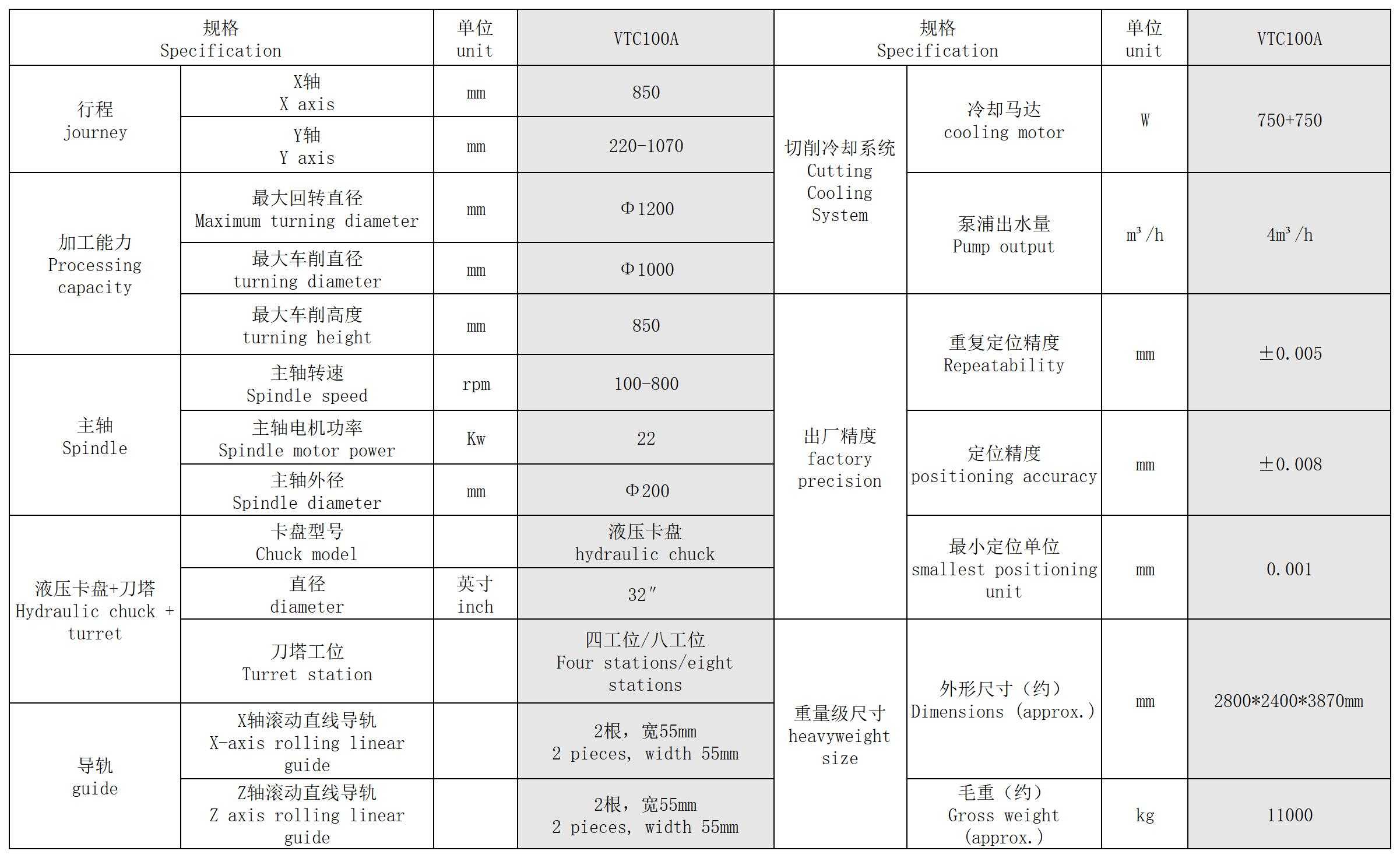

CNC vertical lathe is mainly composed of spindle, chuck, motion control system and other components. The main shaft adopts high-precision bearings, which ensure smooth operation, wear resistance and durability. The chuck adopts high-precision pneumatic clamping, which can ensure high-precision clamping of the workpiece. The motion control system is mainly composed of servo motors and servo motor controllers, which further improves the processing effect and accuracy of CNC vertical lathes.

CNC vertical lathe processing has high accuracy, precision and efficiency, and is widely used in the processing and manufacturing of various parts. This equipment is suitable for different fields such as automated production lines, high-precision manufacturing workshops, education and training institutions, etc., and has extremely high application value and market prospects.

In short, the CNC vertical lathe is a small and popular equipment with stable performance, high processing efficiency, and simple and easy operation. It can help companies save costs and improve production efficiency. It is an essential equipment for you to enhance your competitiveness.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды