- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

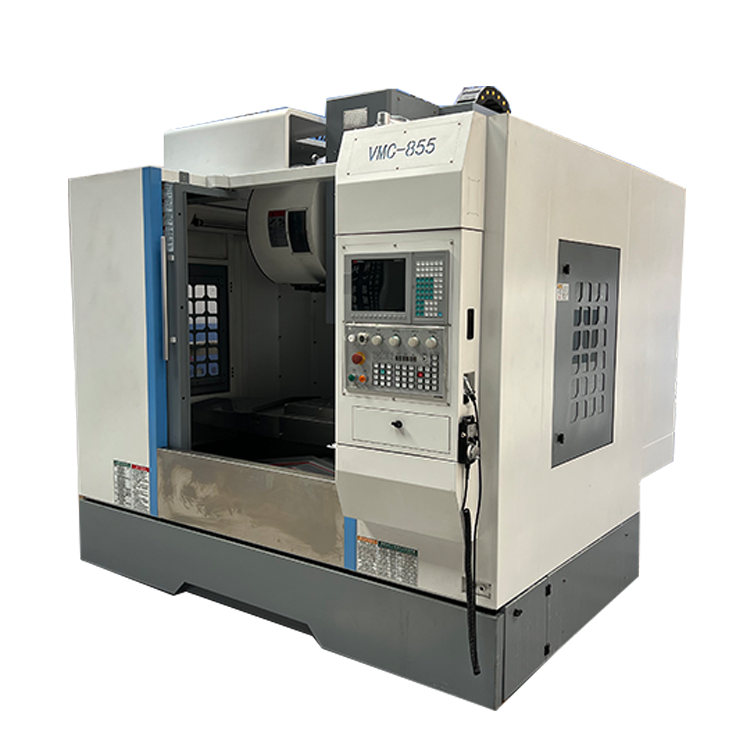

855 vertical high-precision machining center

In the description of "855 vertical machine tool high-precision machining center", "855" refers to a specific model or specification of machine tool....

In the description of "855 vertical machine tool high-precision machining center", "855" refers to a specific model or specification of machine tool. The following are some of the features and functions that a vertical machine tool high-precision machining center may have under normal circumstances:

1. CNC system: Using advanced CNC system, each axis of the machine tool can be controlled through programs to achieve high-precision processing.

2. High-precision guide rail: Equipped with a high-precision guide rail system to ensure the stability and accuracy of the machine tool during movement.

3. Spindle: High-precision spindle usually has higher rotation speed and power to adapt to different processing needs and ensure high-precision cutting.

4. Tool changing system: The automatic tool changing system allows the automatic replacement of different types or sizes of tools during the processing process to improve production efficiency.

5. Workbench: Stable workbench design is suitable for various workpiece clamping methods and ensures high-precision processing.

6. Cooling system: Equipped with a cooling system to cool the cutting area, improve tool life, and ensure stability during processing.

7. High-speed positioning: The fast and accurate positioning system enables the machine tool to achieve high-precision workpiece positioning in a short time.

8. High-resolution position measurement system: used to monitor the position of each axis of the machine tool in real time to ensure high accuracy and repeatability during the machining process.

9. Flexible processing capabilities: Able to adapt to various processing needs, including milling, drilling, tapping and other processing operations.

10. User interface: It has an intuitive user interface, allowing operators to easily set processing parameters and monitor the processing process.

These high-precision machining centers are usually used in industries that require high parts accuracy, such as mold manufacturing, aerospace, machinery industries, etc.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды