- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

CNC machining center ball screw

The ball screw of CNC machining center is an important part of the machine tool transmission system. It is mainly used to convert rotational motion into linear motion to achieve precise positioning and processing of workpieces....

The ball screw of CNC machining center is an important part of the machine tool transmission system. It is mainly used to convert rotational motion into linear motion to achieve precise positioning and processing of workpieces. Its structure and working principle are relatively complex, but its design is exquisite and can achieve high-precision and high-efficiency transmission.

The ball screw of CNC machining center is mainly composed of screw, nut, ball and ball return device. When the screw rod rotates in the CNC machining center, the balls roll between the screw rod and the nut, causing the nut to move linearly in the direction of the screw rod. This rolling friction method greatly reduces transmission resistance, improves transmission efficiency, and also reduces energy loss and wear.

In CNC machining centers, ball screws are widely used and are mainly used in various feeding mechanisms, positioning mechanisms and adjustment mechanisms. The advantage of CNC machining center is that it has the characteristics of high precision, high speed, high rigidity and long life, and can meet the high precision processing needs of complex parts.

In order to maintain the good performance of the ball screw, CNC machining centers require regular maintenance and upkeep. This includes steps such as cleaning, lubrication, inspection and adjustment to ensure proper operation and extended service life of the ball screw.

In addition, when selecting a ball screw, it is necessary to comprehensively consider factors such as the machine tool's specifications, processing accuracy, and load requirements to ensure that the selected ball screw can meet the processing needs of the machine tool.

In short, the ball screw of CNC machining center is an important component in the machine tool transmission system, and its performance directly affects the machining accuracy and efficiency of the machine tool. Therefore, careful selection, installation, care and maintenance are required to ensure the normal operation and processing quality of the machine tool.

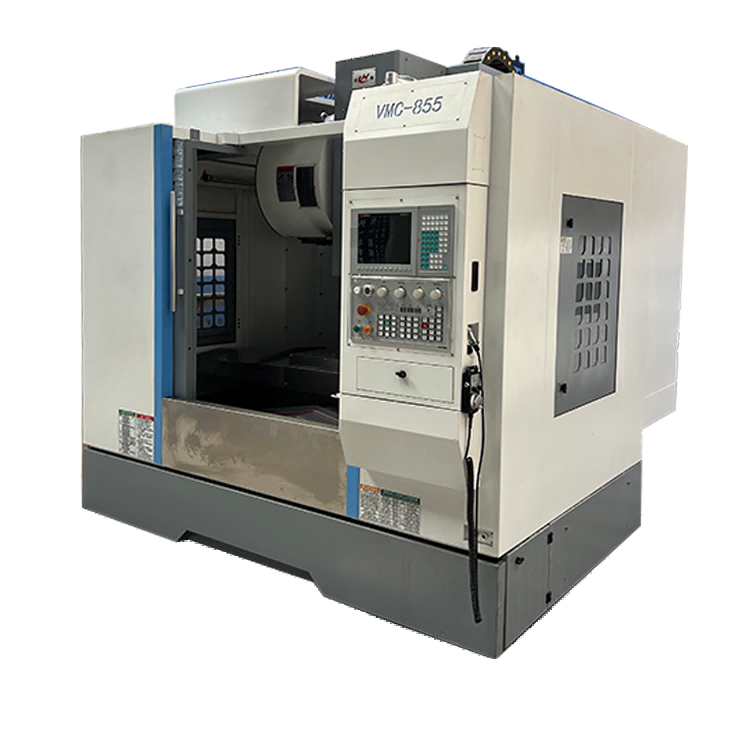

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды