- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

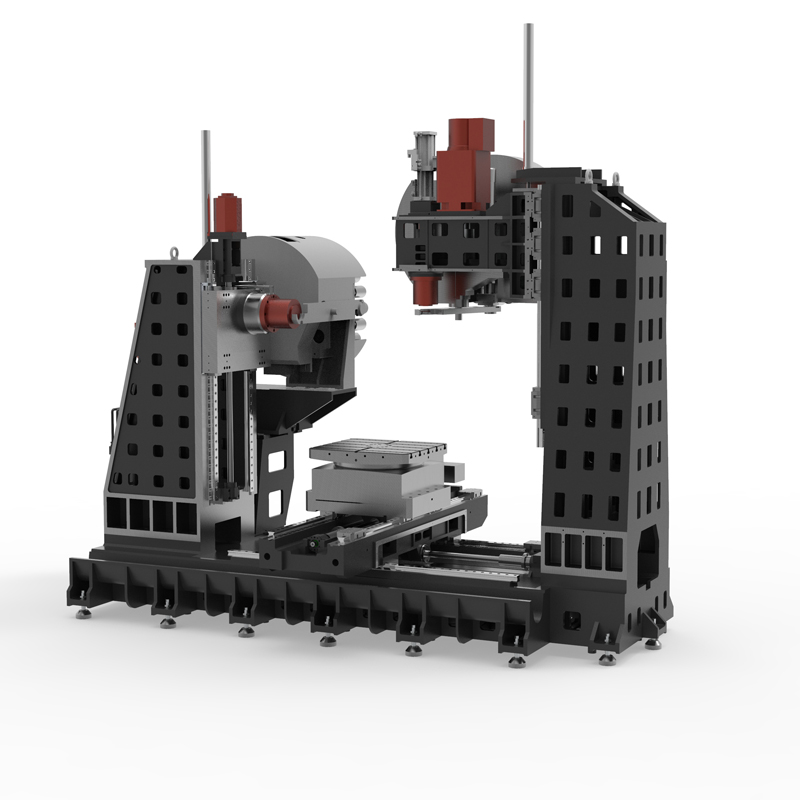

CNC machining center hardware metal processing

CNC machining centers are widely used in the field of hardware and metal processing, mainly including the following aspects:...

CNC machining centers are widely used in the field of hardware and metal processing, mainly including the following aspects:

1. Milling: CNC machining centers can perform milling of various shapes, including plane milling, vertical milling, contour milling, etc. CNC machining centers are used to process various metal hardware parts, such as machine tool beds, parts shells, etc.

2. Drilling: Drilling through the drill bit on the CNC machining center can realize hole processing of various sizes and shapes, and is used to process positioning holes, threaded holes, etc. of hardware parts.

3. Tapping: CNC machining centers can be equipped with tapping tools to realize internal and external thread processing of hardware parts, including common thread specifications such as M6, M8, etc.

4. Boring: Boring is a precision machining method of CNC machining center. The boring tool on the CNC machining center is used to process the inner hole, which can achieve high-precision and high surface quality hole processing. It is suitable for precision holes of hardware parts. processing.

5. Turning: Some CNC machining centers can also perform turning processing, which is used to process the shape and surface of cylindrical parts, such as shaft parts, bushings, etc.

6. Surface treatment: The CNC machining center can also cooperate with various surface treatment processes, such as grinding, polishing, spraying, etc., to perform surface processing on hardware metal parts to improve their surface quality and appearance.

To sum up, CNC machining centers play an important role in the field of hardware and metal processing. They can process parts of various complex shapes and precise sizes, improving production efficiency and product quality.

| Specifications/model | unit | VW50A | VW63A | VW80A | VW50C | VW63B | VW80B | VW50C | VW63C | VW80C | VW63D | VW80D | VW100D |

| Spindle position result | Same side of the cross | Same side of the cross | Same side of the cross | Same side of the cross | Same side of the cross | Same side of the cross | Contralateral simultaneous processing | Contralateral simultaneous processing | Contralateral simultaneous processing | Inverted T-shaped same side | Inverted T-shaped same side | Inverted T-shaped same side | |

| Work content | |||||||||||||

| Horizontal X (left and right), Y (up and down), Z (front and back) | CM | 80、55、550 | 110、60、60 | 130、80、70 | 80、60、50 | 110、80、70 | 130、90、80 | 80、60、50 | 110、80、70 | 130、90、80 | 105、80、60 | 160、80、70 | 200、90、80 |

| Vertical X (left and right), Y (front and back), Z (up and down) | CM | 80、55、550 | 110、60、55 | 130、70、70 | 80、60、60 | 110、70、70 | 130、80、90 | 80、60、60 | 110、70、70 | 130、80、80 | 105、70、70 | 160、80、80 | 200、80、90 |

| Workbench area (can be customized) | MM | 500×500 | 630×630 | 800×800 | 500×500 | 630×630 | 800×800 | 500×500 | 630×630 | 800×800 | 630×630 | 800×800 | 1000×1000 |

| Maximum load | KG | 600 | 800 | 1500 | 600 | 1100 | 1800 | 600 | 1100 | 1800 | 1200 | 1800 | 2200 |

| T-shaped slot (slot width × number of slots) | MM | 18×3 | 20×3 | 22×5 | 18×3 | 22×3 | 22×5 | 18×3 | 22×3 | 22×5 | 22×5 | 28×5 | 28×7 |

| Standard dividing angle of workbench | ℃ | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion | any equal portion |

| Workbench split angle (customized) | ℃ | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 | 1、5、90 |

| Processing range | |||||||||||||

| Distance from horizontal spindle center to worktable | -200+500 | -200+600 | -200+800 | +50-650 | +50-850 | +50-950 | +50-650 | +50-850 | +50-950 | -200+600 | -200+700 | -200+800 | |

| Horizontal spindle nose to the side of the workbench | MM | +100-450 | +100-500 | +100-600 | +100-500 | +150-550 | +200-600 | +100-50 | +150-550 | +200-600 | +100-500 | +100-600 | +100-700 |

| Distance from vertical spindle nose to work surface | MM | +200+750 | +200+800 | +200+900 | +150-750 | +150-850 | +150-1050 | +150-750 | +150-850 | +150-1050 | +200+800 | +200+1000 | +200+1100 |

| Maximum height/diameter of workpiece | MM | 500/900 | 600/1300 | 800/1500 | 500/900 | 600/1300 | 800/1500 | 500/900 | 600/1300 | 800/1500 | 700/900 | 800/1300 | 900/1500 |

| Spindle content | |||||||||||||

| handle form | / | BT40 | BT40 | BT50 | BT40 | BT50 | BT50 | BT40 | BT50 | BT50 | BT50 | BT50 | BT50 |

| Maximum speed of vertical and horizontal spindles | RPM | 8000 | 8000 | 6000 | 8000 | 6000 | 6000 | 8000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Maximum speed of vertical and horizontal spindle (optional) | RPM | 12000 | 12000 | 6000 | 12000 | 6000 | 6000 | 12000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Tool magazine content | / | ||||||||||||

| horizontal structure | / | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm | Robotic arm |

| Maximum tool diameter | MM | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| Maximum tool weight | KG | 8 | 8 | 15 | 8 | 15 | 15 | 8 | 15 | 15 | 15 | 15 | 15 |

| Number of horizontal and vertical tools | T | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 | 24/24 |

| Three-axis rapid traverse speed | M/MIN | 32/32/32 | 32/32/32 | 24/24/24 | 32/32/32 | 32/32/32 | 24/24/24 | 32/32/32 | 32/32/32 | 24/24/24 | 32/32/32 | 24/24/24 | 24/24/24 |

| Axis servo motor | |||||||||||||

| Spindle motor horizontal/vertical | KW | 11/11 | 11/11 | 18.5/18.5 | 11/11 | 18.5/18.5 | 18.5/18.5 | 11/11 | 18.5/18.5 | 18.5/18.5 | 18.5/18.5 | 18.5/18.5 | 18.5/18.5 |

| X, Y, Z axis, B | NM | 22/22/22/12 | 22/22/22/22 | 27/27/27/22 | 22/22/22/22 | 27/27/27/22 | 27/27/27/22 | 22/22/22/22 | 27/27/27/22 | 27/27/27/22 | 27/27/27/22 | 27/27/27/22 | 27/27/27/30 |

| X-axis guide rail, screw rod | MM | Roller 45+screw 40 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 45+screw 40 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 45+screw 40 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 55+screw 50 |

| Y-axis guide rail, screw rod | MM | Roller 45+screw 40 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 45+screw 40 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 45+screw 40 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 55+screw 50 |

| Z-axis guide rail, screw rod | MM | Roller 45+screw 40 | Roller 45+screw 40 | Roller 45+screw 40 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 55+screw 50 | Roller 45+screw 40 | Roller 55+screw 50 | Roller 55+screw 50 | Roller 55+screw 50 | Roller 55+screw 50 | Roller 55+screw 50 |

| air pressure | KG | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 |

| Lubricating oil capacity | L | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| battery capacity | KW | 40 | 40 | 60 | 40 | 60 | 60 | 40 | 60 | 60 | 60 | 60 | 60 |

| Cutting system capacity | L | 450 | 550 | 650 | 450 | 550 | 650 | 450 | 550 | 650 | 450 | 550 | 650 |

| Machine weight | T | 8.0 | 9.5 | 15.5 | 10.5 | 15 | 19.5 | 22 | 27.5 | 33.5 | 22 | 27.5 | 33.5 |

| Machine length (front and rear) | MM | 3600 | 3600 | 4600 | 3600 | 4600 | 4600 | 3900 | 5200 | 5500 | 5200 | 5500 | 6500 |

| Machine width (left and right) | MM | 2800 | 3200 | 4200 | 3200 | 5000 | 5000 | 3600 | 5000 | 5000 | 5000 | 5500 | 6000 |

| Machine height (maximum) | MM | 3300 | 3300 | 2700 | 3300 | 3700 | 3700 | 3300 | 3700 | 3700 | 4100 | 4300 | 4700 |

| Chip removal method (optional) | / | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate |

| Chip removal method (optional) | / | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw |

| controller system | CNC | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel | multi-channel |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды