- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

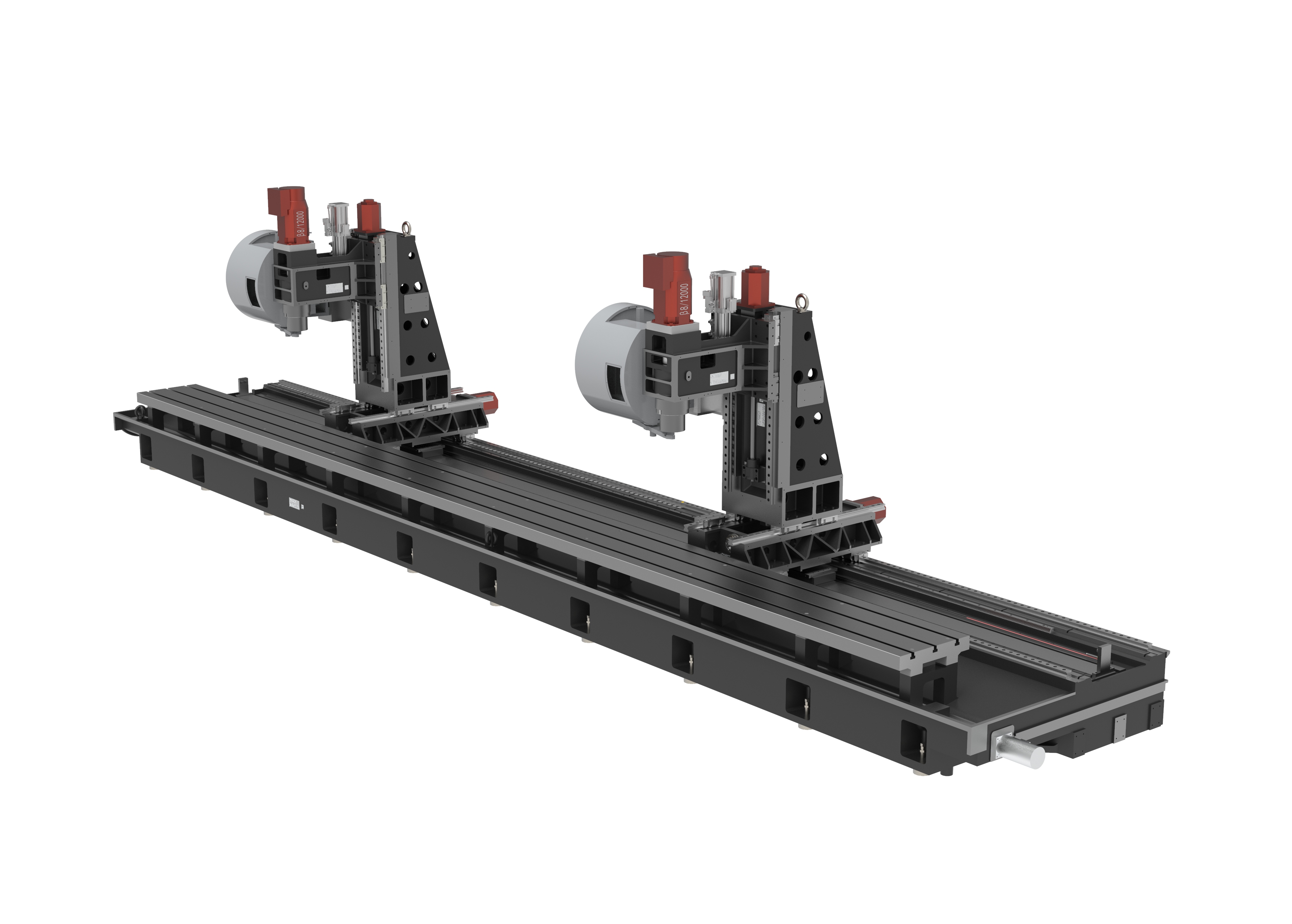

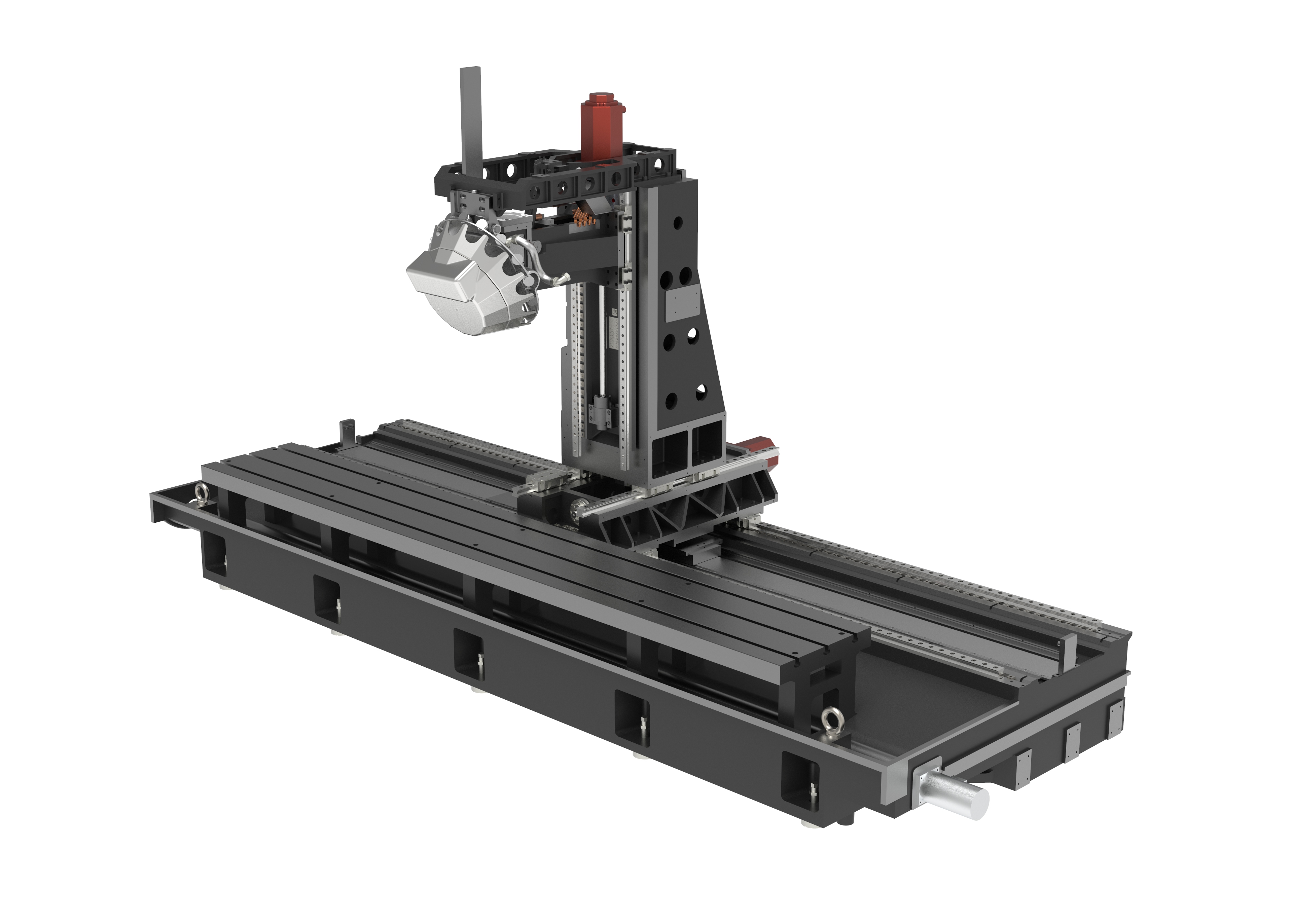

Column mobile machining center

The column mobile machining center is a CNC machine tool with a column structure and the worktable moves in the longitudinal direction of the column....

The column mobile machining center is a CNC machine tool with a column structure and the worktable moves in the longitudinal direction of the column. The following are the features of column mobile machining centers:

1. Column structure: The column structure of the column mobile machining center is integral or steel casting, which provides good stability and rigidity, allowing the whole machine to maintain stability during high-speed cutting.

2. Longitudinal movement of the worktable: The worktable of the column mobile machining center moves in the longitudinal direction of the column. This structure allows the machining center column to be simplified, while also providing a larger processing space and higher processing accuracy.

3. High-speed and high-precision processing: Column mobile machining centers are usually equipped with high-performance spindles and servo systems, which can achieve high-speed and high-precision processing to meet the processing needs of complex parts.

4. Multi-axis processing capabilities: Some column mobile machining centers have multi-axis processing capabilities, such as three-axis, four-axis, five-axis or even more axis processing capabilities, which can achieve more complex parts processing.

5. Wide range of applications: The column mobile machining center is suitable for processing a variety of materials, including metals, plastics, composite materials, etc., and is widely used in aerospace, automobile manufacturing, mold manufacturing and other fields.

6. High degree of automation: Column mobile machining centers are usually equipped with CNC systems, which can realize automated control and programming, improving production efficiency and processing accuracy.

In general, the column mobile machining center has become one of the indispensable and important processing equipment in modern manufacturing industry with its stable structure, high-speed and high-precision processing capabilities and wide range of applications.

| Specifications/model | unit | SVA/T2050 | SVA/T2250 | SVA/T3050 | SVA/T3550 | SVA/T4550 |

| working desk size | MM | 2500×500 | 3000×500 | 3000×500 | 4000×500 | 5000×500 |

| X×Y axis travel | MM | 2000×550 | 2500×550 | 3000×550 | 3500×550 | 4500×550 |

| Z-axis travel/select | MM | 550/700 | 550/700 | 550/700 | 550/700 | 550/700 |

| SVA/T Y70 series-column mobile machining center | ||||||

| Specifications/model | unit | SVA/T2070 | SVA/T2570 | SVA/T3070 | SVA/T3570 | SVA/T4570 |

| working desk size | MM | 2500×700 | 3000×700 | 3000×700 | 4000×700 | 5000×700 |

| X×Y axis travel | MM | 2000×700 | 2500×700 | 3000×700 | 3500×700 | 4500×700 |

| Z-axis travel | MM | 550/700 | 550/700 | 550/700 | 550/700 | 550/700 |

| SVB-Y80 series-column mobile machining center | ||||||

| Specifications/model | unit | SVC3580 | SVC4580 | SVC6580 | SVC8580 | SVC10580 |

| working desk size | MM | 4000×800 | 5000×800 | 7000×800 | 9000×800 | 11000×800 |

| X×Y axis travel | MM | 3500×800 | 4500×800 | 6500×800 | 8500×800 | 10500×800 |

| Z-axis travel | MM | 800 | 800 | 800 | 800 | 800 |

| SVB-Y120 series-column mobile machining center | ||||||

| Specifications/model | unit | SVC3512 | SVC4512 | SVC6512 | SVC8512 | SVC10512 |

| working desk size | MM | 4000×1200 | 5000×1200 | 12000×1200 | 9000×1200 | 11000×1200 |

| X×Y axis travel | MM | 3500×1200 | 4500×1200 | 6500×1200 | 8500×1200 | 10500×1200 |

| Z-axis travel | MM | |||||

| Tool magazine structure: disc robot arm type A, clamp arm type T type | ||||||

| Spindle specification A (standard) | BT | BT40-150 | ||||

| Spindle speed | RPM | 12000 | ||||

| Tool magazine capacity | BT40-24 | |||||

| Spindle specification T (optional) | BT | BT40-140 | ||||

| Spindle speed | RPM | 12000 |

| Specifications/model | unit | SVA/T6550 | SVA/T8550 | SVA/T10550 | SVA/T12505 |

| working desk size | MM | 7000×500 | 9000×500 | 11000×500 | 13000×5000 |

| X×Y axis travel | MM | 6500×550 | 8500×550 | 10500×550 | 12500×550 |

| Z-axis travel/select | MM | 550/700 | 550/700 | 550/700 | 550/700 |

| SVA/T Y70 series-column mobile machining center | |||||

| Specifications/model | unit | SVA/T6570 | SVA/T8570 | SVA/T10570 | SVA/T12507 |

| working desk size | MM | 7000×700 | 9000×700 | 11000×700 | 13000×700 |

| X×Y axis travel | MM | 6500×700 | 8500×700 | 10500×700 | 12500×700 |

| SVB-Y80 series-column mobile machining center | |||||

| Specifications/model | unit | SVC12580 | |||

| working desk size | MM | 13000×800 | |||

| X×Y axis travel | MM | 12500×800 | |||

| Z-axis travel | MM | 800 | |||

| SVB-Y120 series-column mobile machining center | |||||

| Specifications/model | unit | SVC12512 | |||

| working desk size | MM | 13000×1200 | |||

| X×Y axis travel | MM | 12500×1200 | |||

| Z-axis travel | MM | 1200 | |||

| Tool magazine structure: disc robot arm type A, clamp arm type T type | |||||

| Spindle specification A (standard) | BT |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды