- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

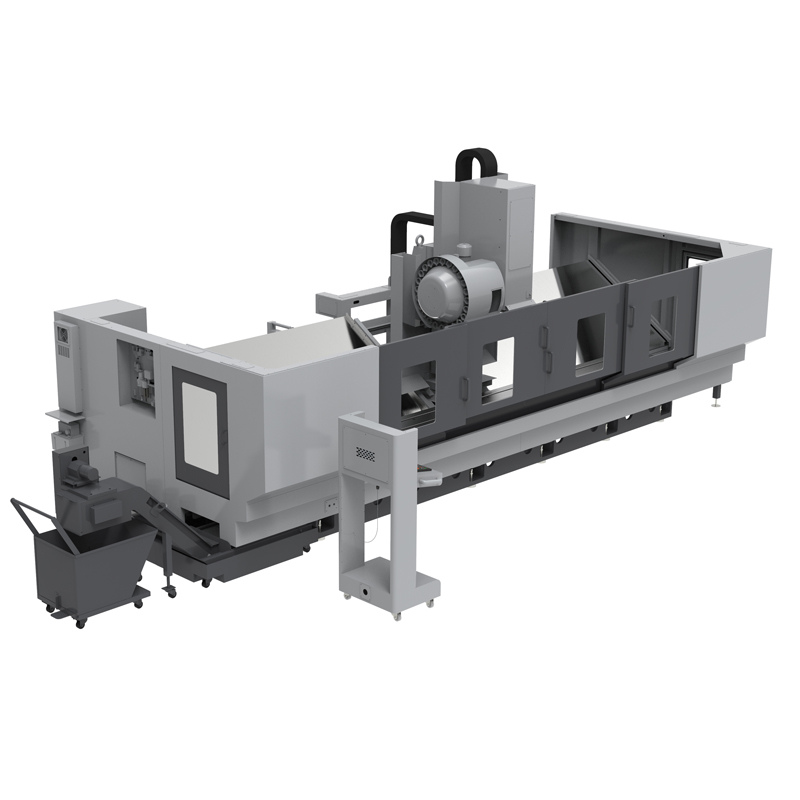

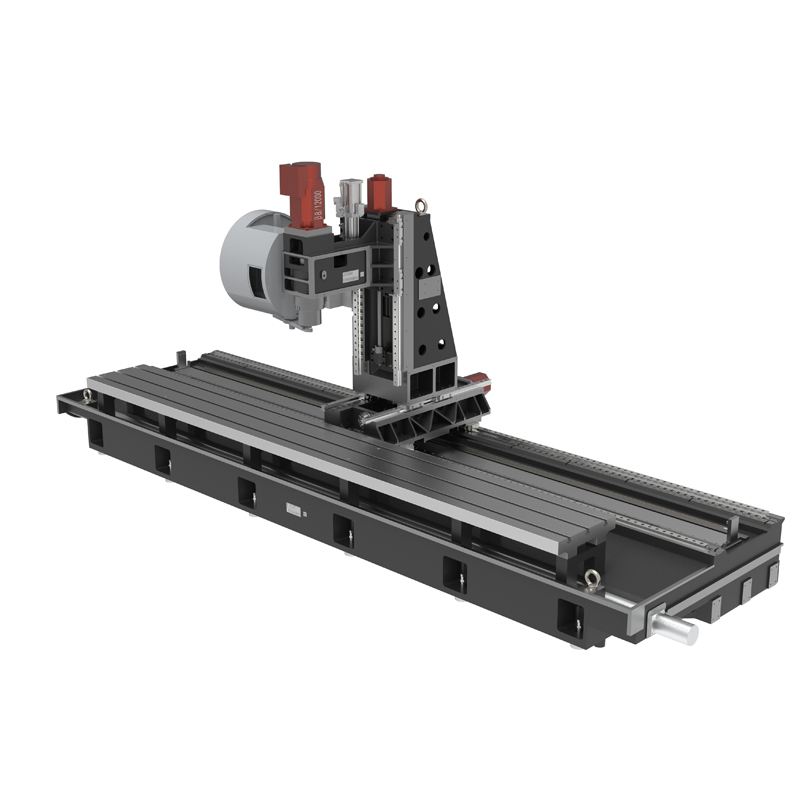

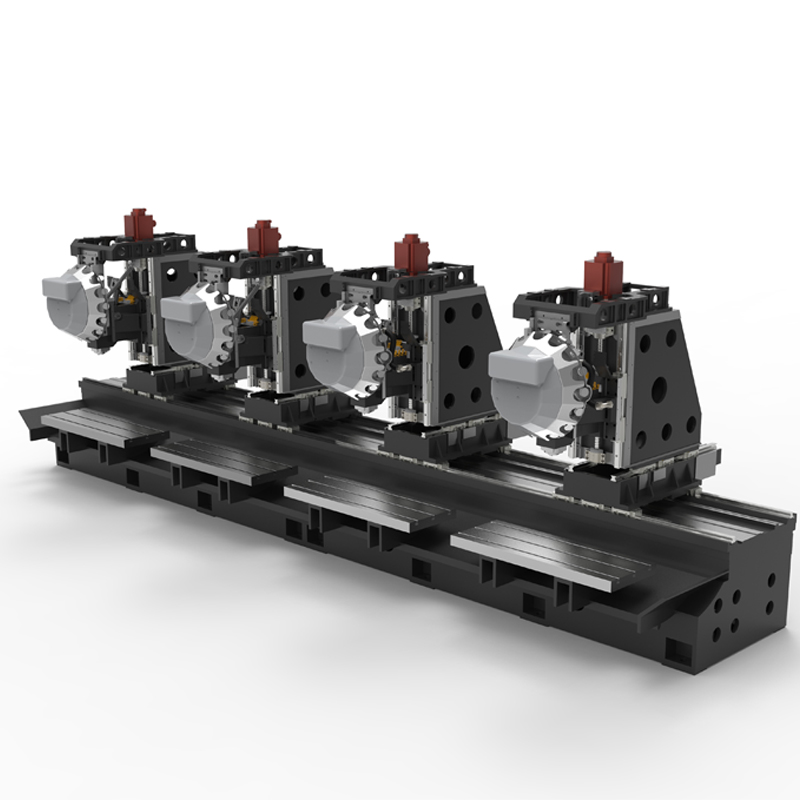

Light gantry mobile machining center

The lightweight gantry mobile machining center is a flexible and efficient CNC machining equipment that is often used for high-precision machining of large workpieces....

The lightweight gantry mobile machining center is a flexible and efficient CNC machining equipment that is often used for high-precision machining of large workpieces. It has the following characteristics:

1. Gantry structure: The lightweight gantry mobile machining center adopts a gantry structure, which has good stability and rigidity and is suitable for high-precision processing of large workpieces.

2. Mobile design: The lightweight gantry mobile machining center can move within the processing area, making the processing range larger, and can process workpieces of various sizes, improving the flexibility and diversity of processing.

3. Lightweight design: The lightweight gantry mobile machining center adopts a lightweight structure design, has a small dead weight, is easy to move and arrange, and is suitable for various production scenarios.

4. Multi-function processing: Light-weight gantry mobile machining centers are usually equipped with a variety of processing functions, such as milling, drilling, tapping, etc., to meet the processing needs of different workpieces.

5. CNC system: The lightweight gantry mobile machining center is equipped with an advanced CNC system with high-precision position control and processing functions, which can achieve efficient processing of complex workpieces.

6. Automation functions: The lightweight gantry mobile machining center is equipped with automatic tool changing systems, automatic feeding systems and other automation functions, which further improves production efficiency.

7. Easy to maintain: The lightweight gantry mobile machining center has a simple structure and is easy to maintain and maintain, reducing downtime and improving the reliability and stability of the equipment.

Lightweight gantry mobile machining centers are widely used in aerospace, automobile manufacturing, mold manufacturing and other fields, and can meet the processing needs for larger workpiece sizes and higher precision requirements.

| Specifications/model | unit | SVA/T2050 | SVA/T2250 | SVA/T3050 | SVA/T3550 | SVA/T4550 |

| working desk size | MM | 2500×500 | 3000×500 | 3000×500 | 4000×500 | 5000×500 |

| X×Y axis travel | MM | 2000×550 | 2500×550 | 3000×550 | 3500×550 | 4500×550 |

| Z-axis travel/select | MM | 550/700 | 550/700 | 550/700 | 550/700 | 550/700 |

| SVA/T Y70 series-column mobile machining center | ||||||

| Specifications/model | unit | SVA/T2070 | SVA/T2570 | SVA/T3070 | SVA/T3570 | SVA/T4570 |

| working desk size | MM | 2500×700 | 3000×700 | 3000×700 | 4000×700 | 5000×700 |

| X×Y axis travel | MM | 2000×700 | 2500×700 | 3000×700 | 3500×700 | 4500×700 |

| Z-axis travel | MM | 550/700 | 550/700 | 550/700 | 550/700 | 550/700 |

| SVB-Y80 series-column mobile machining center | ||||||

| Specifications/model | unit | SVC3580 | SVC4580 | SVC6580 | SVC8580 | SVC10580 |

| working desk size | MM | 4000×800 | 5000×800 | 7000×800 | 9000×800 | 11000×800 |

| X×Y axis travel | MM | 3500×800 | 4500×800 | 6500×800 | 8500×800 | 10500×800 |

| Z-axis travel | MM | 800 | 800 | 800 | 800 | 800 |

| SVB-Y120 series-column mobile machining center | ||||||

| Specifications/model | unit | SVC3512 | SVC4512 | SVC6512 | SVC8512 | SVC10512 |

| working desk size | MM | 4000×1200 | 5000×1200 | 12000×1200 | 9000×1200 | 11000×1200 |

| X×Y axis travel | MM | 3500×1200 | 4500×1200 | 6500×1200 | 8500×1200 | 10500×1200 |

| Z-axis travel | MM | |||||

| Tool magazine structure: disc robot arm type A, clamp arm type T type | ||||||

| Spindle specification A (standard) | BT | BT40-150 | ||||

| Spindle speed | RPM | 12000 | ||||

| Tool magazine capacity | BT40-24 | |||||

| Spindle specification T (optional) | BT | BT40-140 | ||||

| Spindle speed | RPM | 12000 |

| Specifications/model | unit | SVA/T6550 | SVA/T8550 | SVA/T10550 | SVA/T12505 |

| working desk size | MM | 7000×500 | 9000×500 | 11000×500 | 13000×5000 |

| X×Y axis travel | MM | 6500×550 | 8500×550 | 10500×550 | 12500×550 |

| Z-axis travel/select | MM | 550/700 | 550/700 | 550/700 | 550/700 |

| SVA/T Y70 series-column mobile machining center | |||||

| Specifications/model | unit | SVA/T6570 | SVA/T8570 | SVA/T10570 | SVA/T12507 |

| working desk size | MM | 7000×700 | 9000×700 | 11000×700 | 13000×700 |

| X×Y axis travel | MM | 6500×700 | 8500×700 | 10500×700 | 12500×700 |

| SVB-Y80 series-column mobile machining center | |||||

| Specifications/model | unit | SVC12580 | |||

| working desk size | MM | 13000×800 | |||

| X×Y axis travel | MM | 12500×800 | |||

| Z-axis travel | MM | 800 | |||

| SVB-Y120 series-column mobile machining center | |||||

| Specifications/model | unit | SVC12512 | |||

| working desk size | MM | 13000×1200 | |||

| X×Y axis travel | MM | 12500×1200 | |||

| Z-axis travel | MM | 1200 | |||

| Tool magazine structure: disc robot arm type A, clamp arm type T type | |||||

| Spindle specification A (standard) | BT |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды