- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

machining center manufacturers

CNC vertical machining center is a commonly used CNC machine tool, mainly used for processing complex parts such as plates, disks, molds and small shells....

CNC vertical machining center is a commonly used CNC machine tool, mainly used for processing complex parts such as plates, disks, molds and small shells. Its spindle axis is set perpendicular to the workbench, which makes the clamping and positioning of workpieces more convenient, and the movement trajectory of the cutting tool is also easy to observe. The vertical machining center has the advantages of small footprint and simple structure. A CNC vertical machining center is a CNC machine tool that has a vertical layout and is capable of performing a variety of machining operations such as milling, drilling, tapping, etc. The following is a general introduction to CNC vertical machining centers:

1. Vertical layout: This means that the spindle of the CNC vertical machining center is perpendicular to the workbench, the workpiece is fixed on the workbench, and the spindle moves in the vertical direction. This layout facilitates efficient processing in a relatively small space.

2. CNC technology: The CNC vertical machining center adopts CNC technology, which uses a computer control system to realize the movement of each axis of the machine tool and the operation of the tools and cutting tools. This makes the machining process more automated, precise and flexible.

3. Multi-function processing: CNC vertical machining centers usually have multiple processing functions, such as milling, drilling, tapping, engraving, etc. This makes it suitable for a variety of process needs and capable of completing the processing of complex parts.

4. High-precision processing: The application of CNC technology enables CNC vertical machining centers to achieve high-precision processing, and is suitable for fields that require high workpiece accuracy, such as mold manufacturing, aerospace, etc.

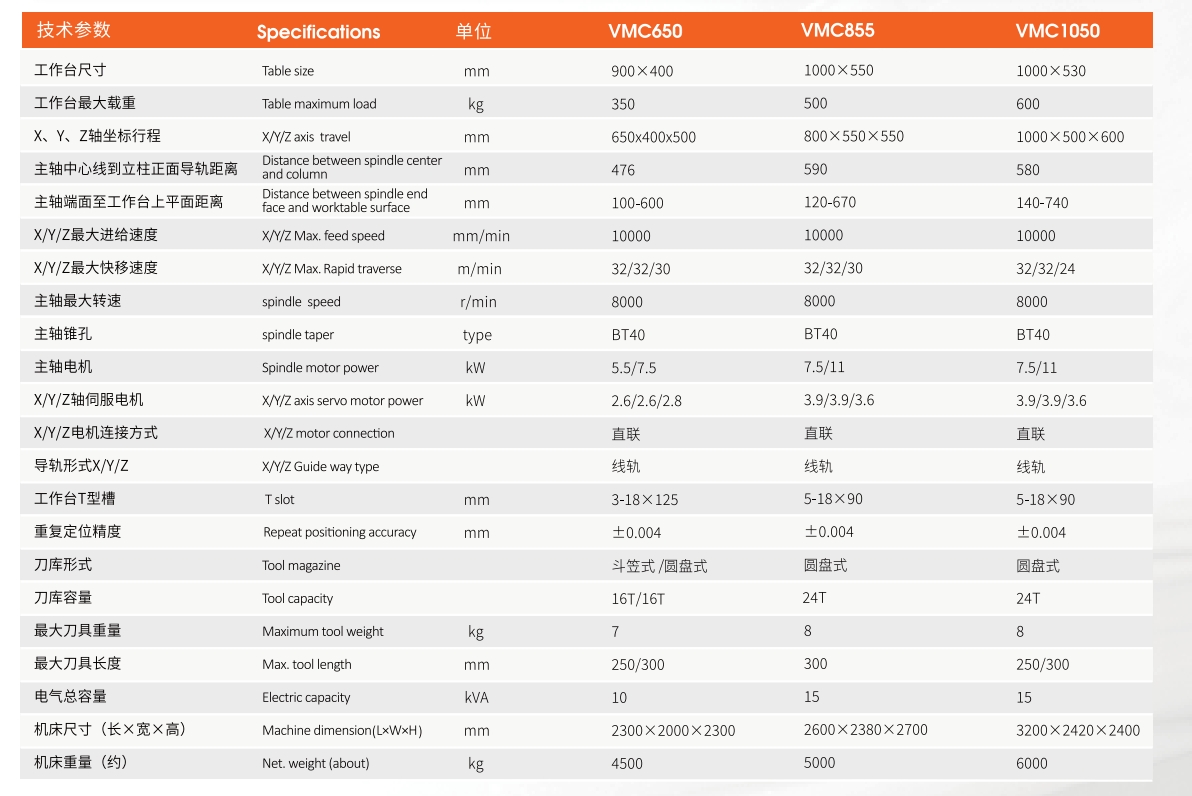

5. Automatic tool changing system: In order to improve production efficiency, CNC vertical machining centers are usually equipped with automatic tool changing systems, which can automatically change different types or specifications of tools during the machining process.

6. Worktable rotation function: Some CNC vertical machining centers also have a worktable rotation function, making processing at different angles more convenient.

CNC vertical machining center is an efficient and high-precision CNC machine tool suitable for processing various complex parts. These characteristics make CNC vertical machining centers an efficient and precise machine tool widely used in the manufacturing industry, suitable for producing a variety of industrial parts and components.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды